Welcome

Welcome to Realtime training. Depending on your role at Intelligent Door Solutions, you will have been allocated relevant sections to work through. These sections are planned to be worked through in order, so you won't be able to skip a section, you must read and confirm that you understand before moving to the next area.

Once you have completed all of your training you will receive an email confirming this.

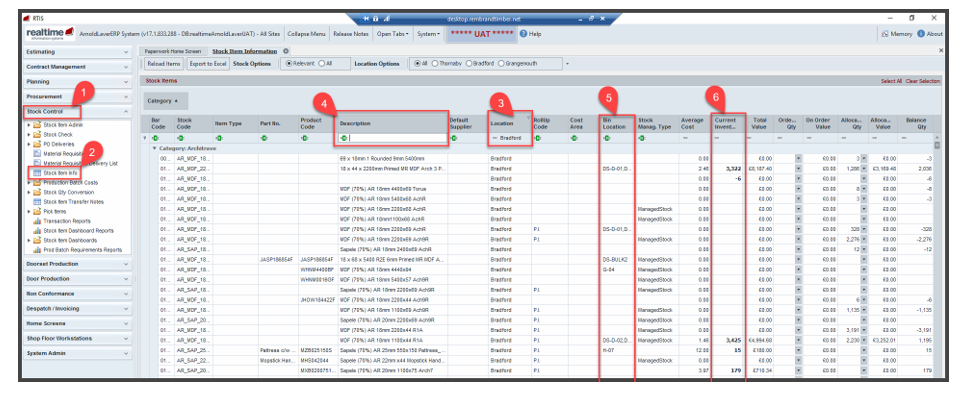

Start now by watching this short video

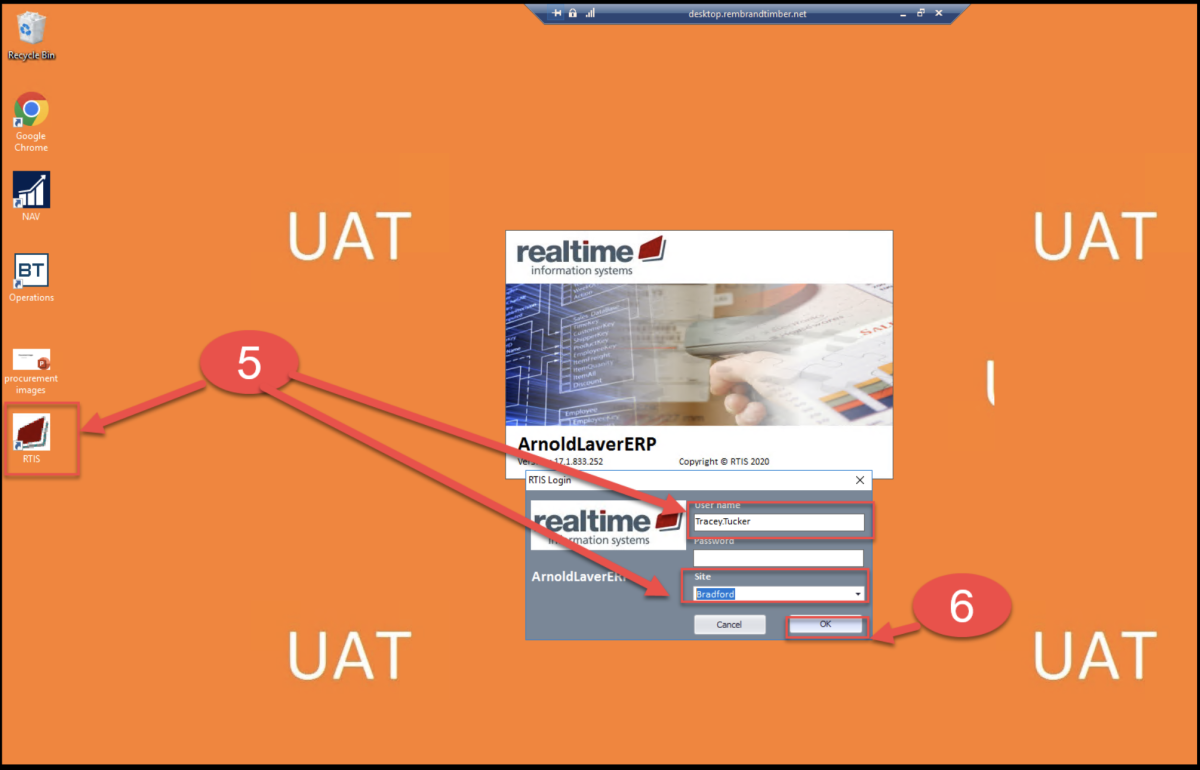

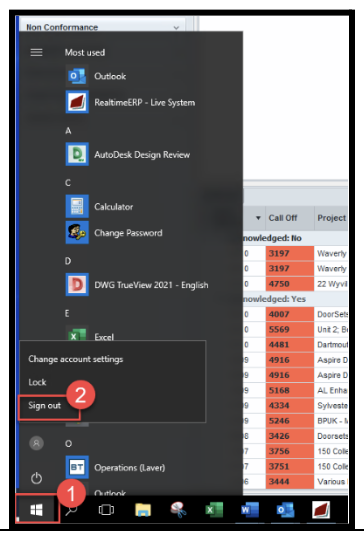

How to access UAT

IT will provide you with UAT log in details once you have these follow the steps below to access UAT. UAT is where training is completed and is a copy of the live system.

IT contact number, if required, is 0114 276 4855.

Select the RDP -UAT System icon from your desktop – if not on desktop call IT for assistance

Enter your password and select OK this will have been given to you prior to your first training session. If you cannot recall this or it has expired call IT and ask for support

UAT new window opens, this is bright orange, select the Rtis icon

New log in window opens, enter your username, IT will provide you with your password, select your site

Click OK

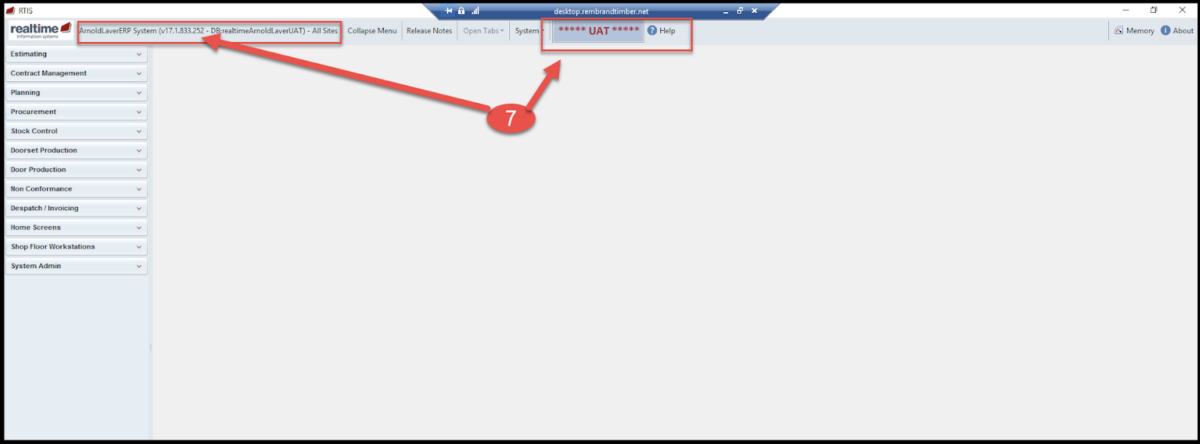

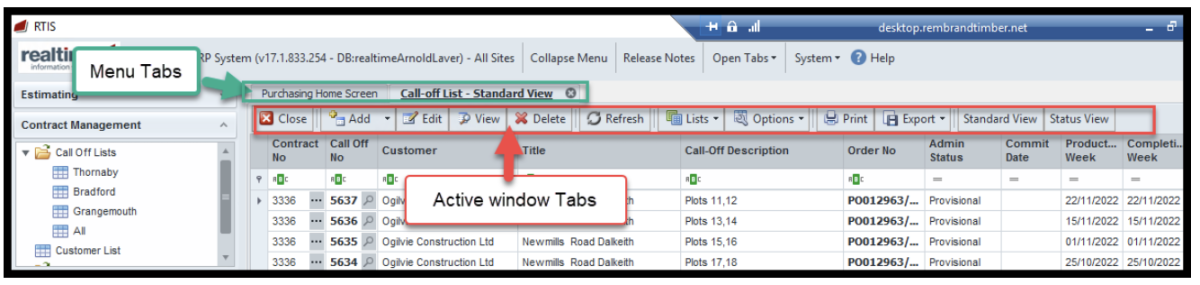

How to navigate around Realtime

Below will help with navigation around Rtis / Real time

Version – it is very useful to know what version of Realtime you are using

Image 1 when first logging in

Image 2 always on show

When asked what version you have it is the last 3 digits that are important

Spy Glass – select the spy glass to see keys documents attached to the contact

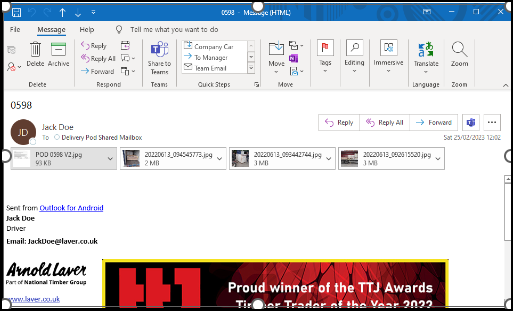

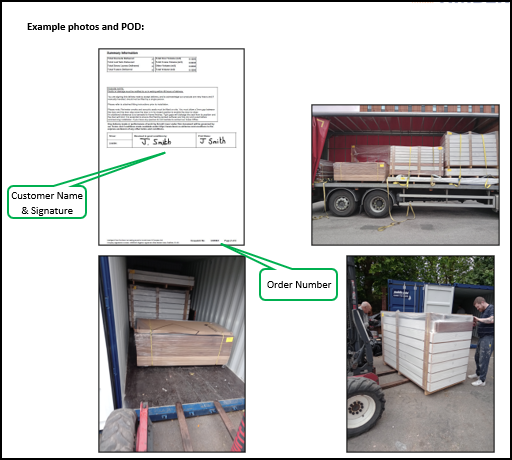

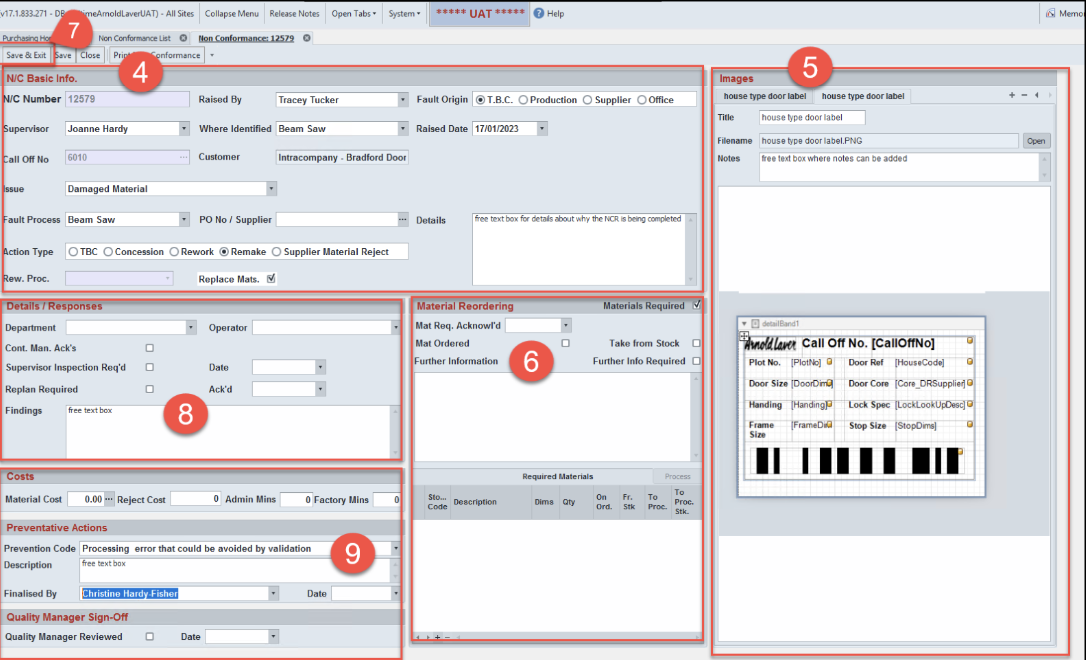

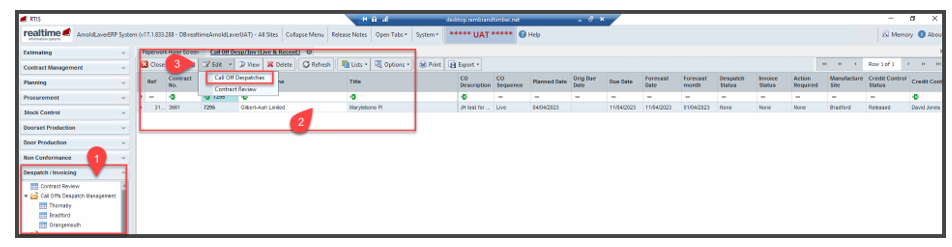

- POD

- Despatch Note

- Customer Purchase order

- Customer Invoice

Refresh – this tab is available on many screens and key when working in one screen for a long period of time

How to Continue to Communication

This is a reminder that once Rtis/Realtime replaces Bistrack it is essential that verbal and other ways you communicated whilst using Bistrack that these CONTINUE

Rtis/Realtime is a new computer system to support Intelligent doors keeping all process and the journey of a customers order all in one place here is a link to the Welcome to Realtime v1.7

Rtis/Realtime does NOT replace communication that currently takes place unless instructed otherwise

Throughout the individual Process documents reminders are included about which departments may be affected by certain actions, below is an example of how valuable communication is to ensure a seamless process for the business ensuring the customer receives their order on time

Communication is key in our business – don’t forget to TALK and share information with teams that are affected by changes that are made

Example - Customer requests a date change – Depending on the status of the order the below departments all need to be communicated BEFORE changes are agreed and made.

Purchasing

Planning

Production

Despatch /Transport

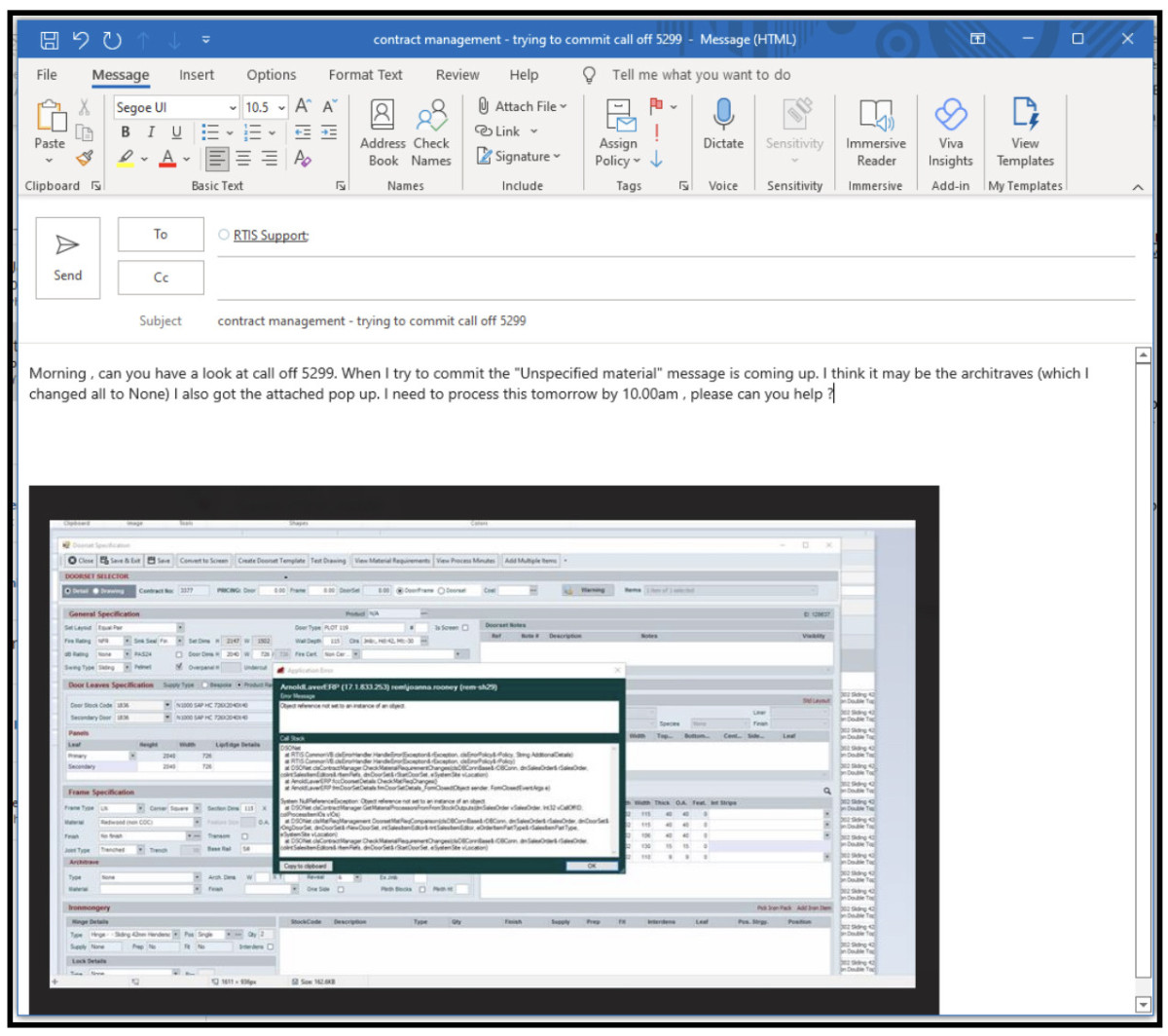

Help and Support

email support@nationaltimbergroup.comWhen you have a question/request for support/ in need of help

In the subject field of the email state the function you are requesting help with and the call off no/invoice no/dispatch no/PO No your question relates to.

In the body of the email explain what help is needed, a screen shot would be useful.

State when you need to complete the task you are asking about, this will help prioritises the request.

Useful contacts

Here are a list of useful contacts.

Technical & Compliance Questions: - tec help desk on Mondays.com

Need a product code creating - contact purchasing or an onsite superuser by emailing purchasing@inteldoors.co.uk

Set up a new customer – forms are completed by BDM sent Credit control when approved link the account in Realtime

Set up a new supplier – form supplier agreement – contact purchasing@inteldoors.co.uk or via the help desk on Mondays .com

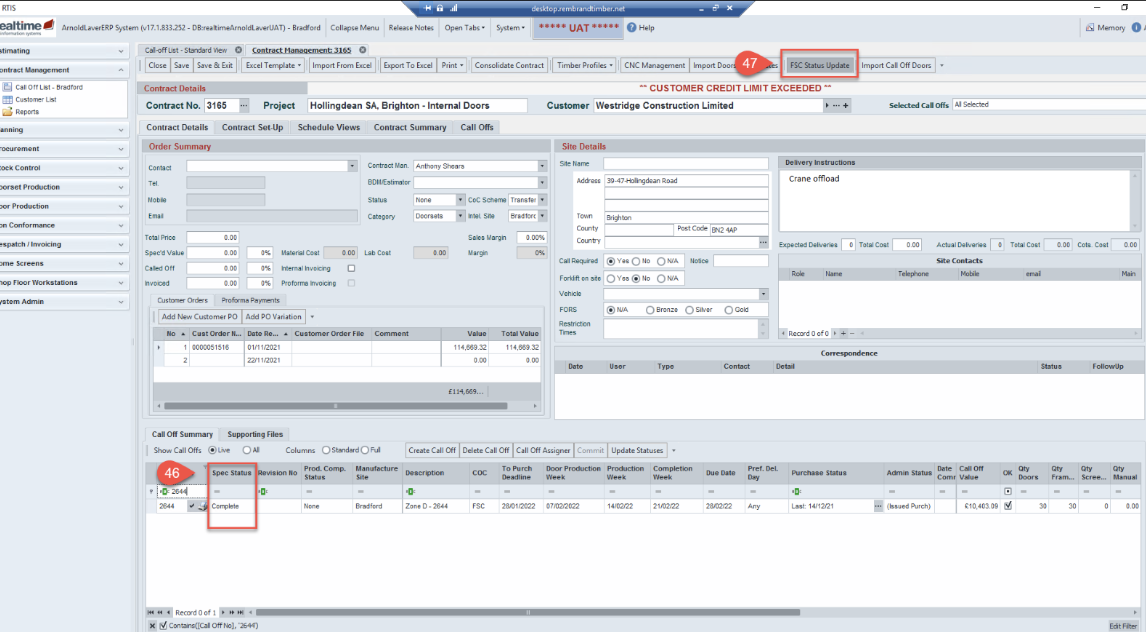

Customer over credit limit – Email credit control – Add here your credit controller email and telephone number

CC Name Telephone Number

Email address

Issues accessing remote desktop - IT Help Desk - 0114 276 4855 or email support@nationaltimbergroup.com

Access to Process steps/Training documents – any issue with accessing documents email rtissupport@nationaltimbergroup.com

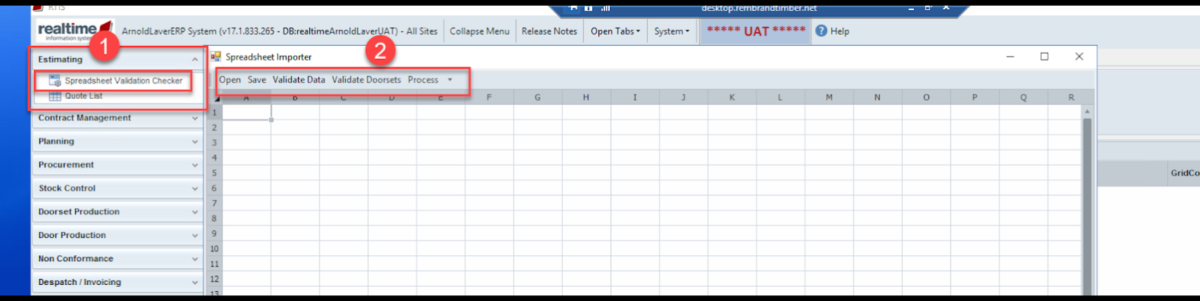

Estimating

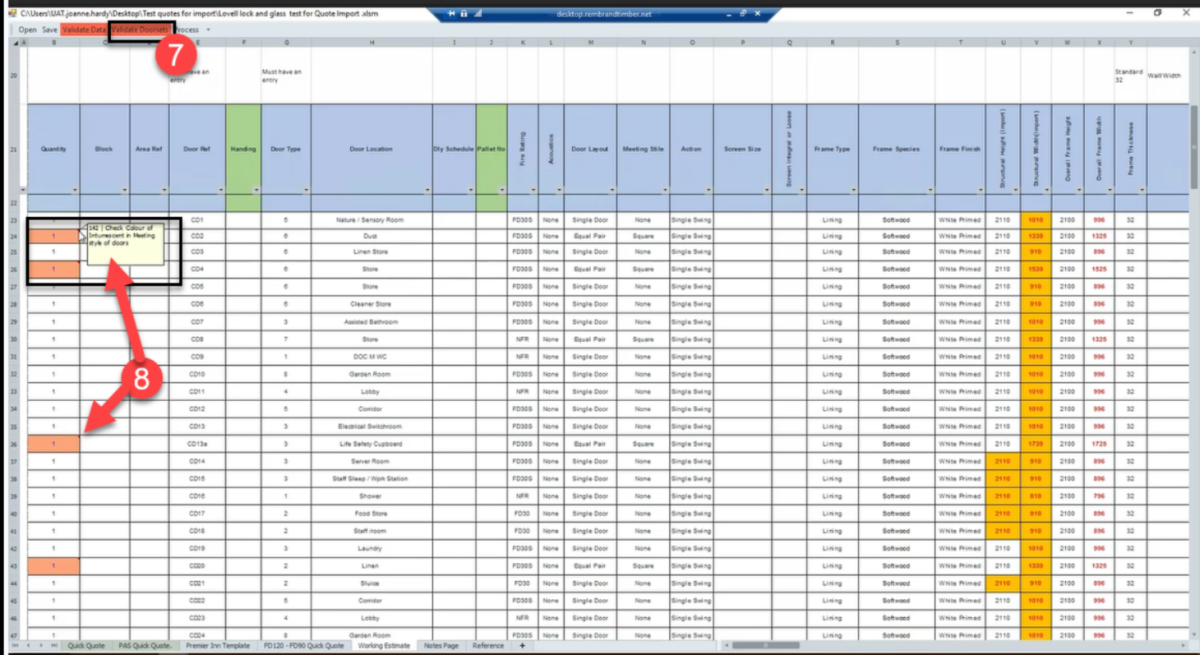

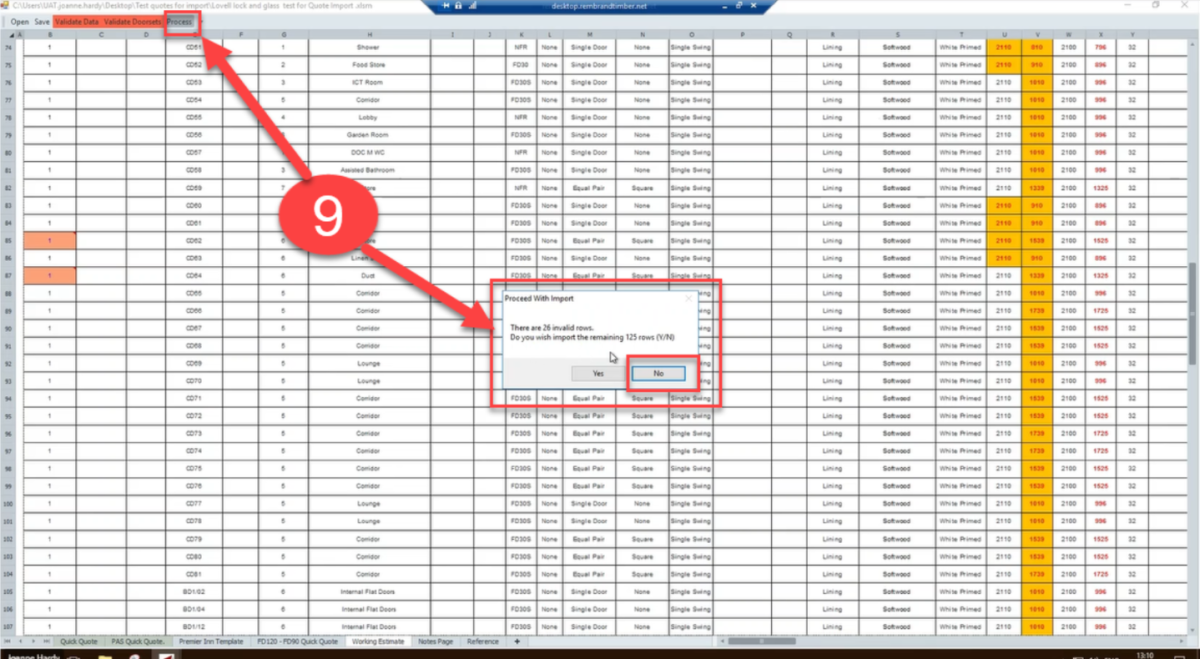

How to use the spreadsheet validation checker

How to Use the spread sheet Validation checker

This is a great function within Rtis, here the customers spreadsheet with their specification on can be checked prior to being imported into the quote.

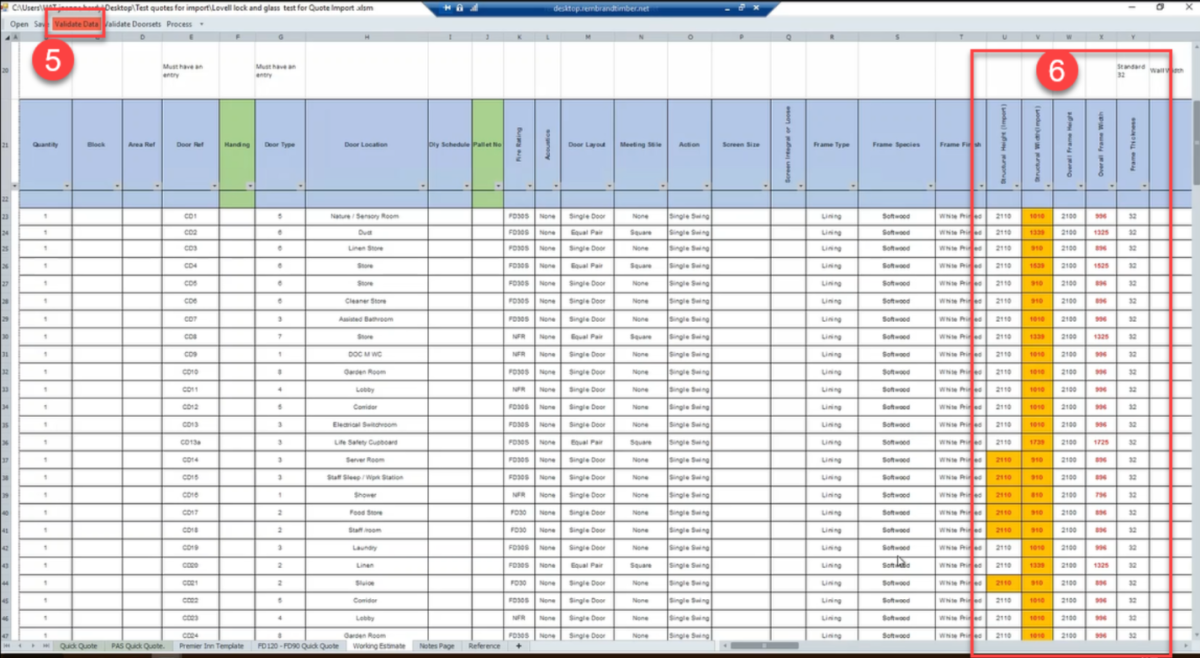

This opens new window start by selecting the Open tab this opens local files to locate the spreadsheet for validating;

Other tabs used in this process are as follows

Save –

Validate Date –

Validate Doorsets

Process -

Example here shows the validate data tab has gone RED this means there are errors within the data that need to be corrected before proceeding.

Select the comments in the highlighted cell this will reveal the error and what needs to be checked continue to check the whole sheet for these comments and fix before proceeding.

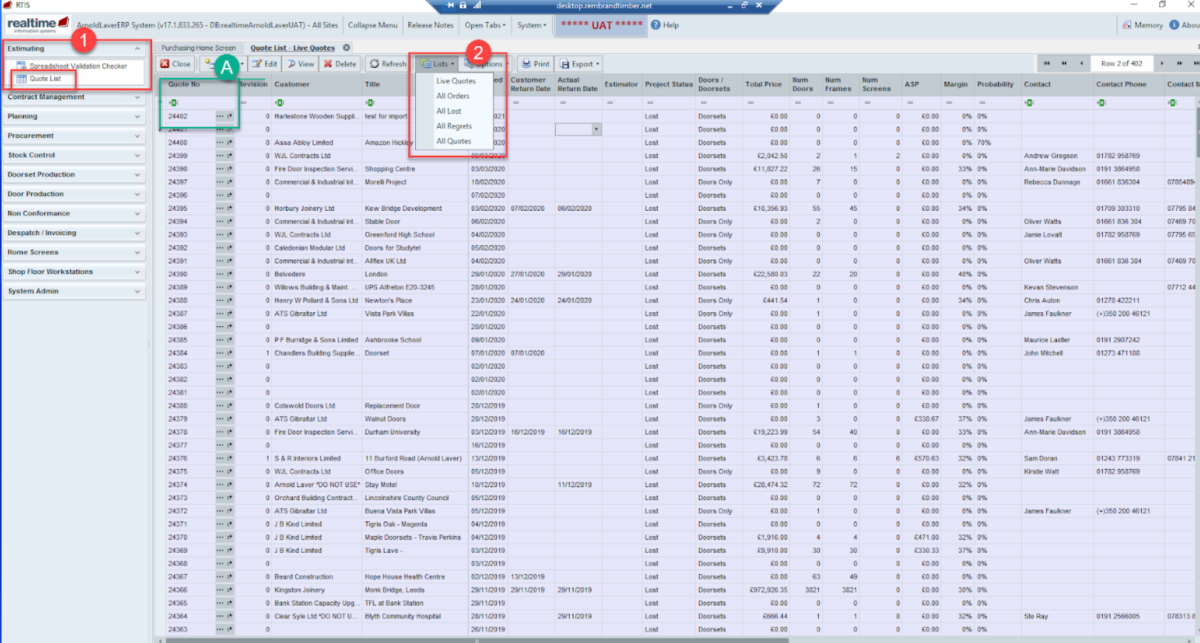

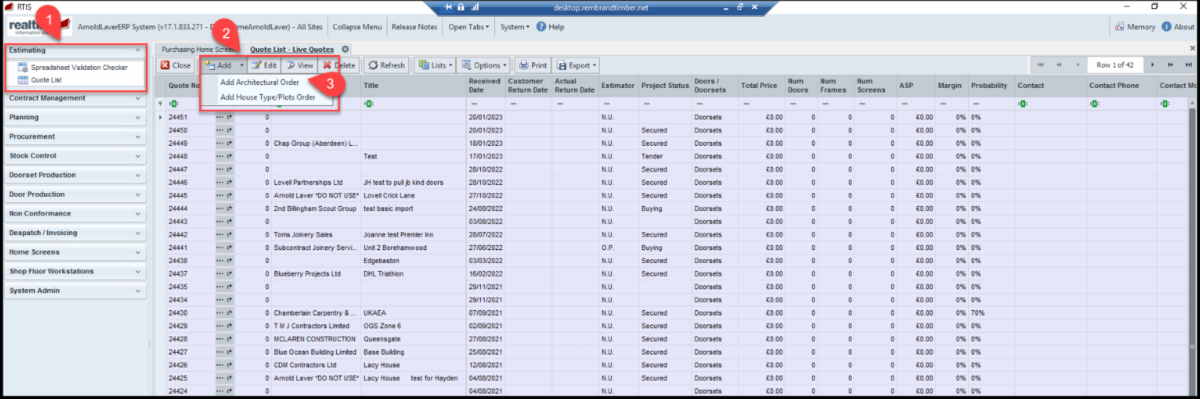

How to use the Quote List

This view allows to be able to see the status of quotes by selecting lists tab the quotes can be sorted into

Live Quotes – all quotes still open

All Orders – means Quotes

All Lost – Shows all quotes with a status of lost

All Regrets – Business decision to abstain from quoting

All Quotes – Shows all regardless of status

Column details This information is pulled from the actual quote if information is missing this is due to the information not inputted

Quote No - Unique number given to quote as it is raised

Revision – version if the quote is revised

Customer – Customer name

Tittle - Name of quote/project

Received Date – Date quote request received

Customer Return Date – date customer requires the quote returned

Actual Return Date – Date actually returned to customer

Estimator – Name of estimator who created quote/quoted prices

Project status - Choices are - buying-Lost -Order- Secured- Tender

Door/Doorsets - Choices are – Door kits – Doors only – Doorsets- Frames only

Total Price - Value of quote

Num Doors – Actual number of doors

Num Frames – Actual number of frames

Num Scr – Actual number of screens

ASP – Average selling price

Margin – Margin percentage made on the quote

Probability – Choices are 0% - 30%- 50% - 70%- 90%

Follow up – Date when quote will be followed up

Contact – Person to contact

Contact Phone - Contact telephone number

Contact Mobile – Contacts mobile Number

Contact email – Contacts email address

Project scope – Comments added here by estimator

Quote Folder – Option to upload folders by selecting pick a folder -currently not used as all information in Mondays.com SharePoint

Intel Site – Shows site where the quote was raised

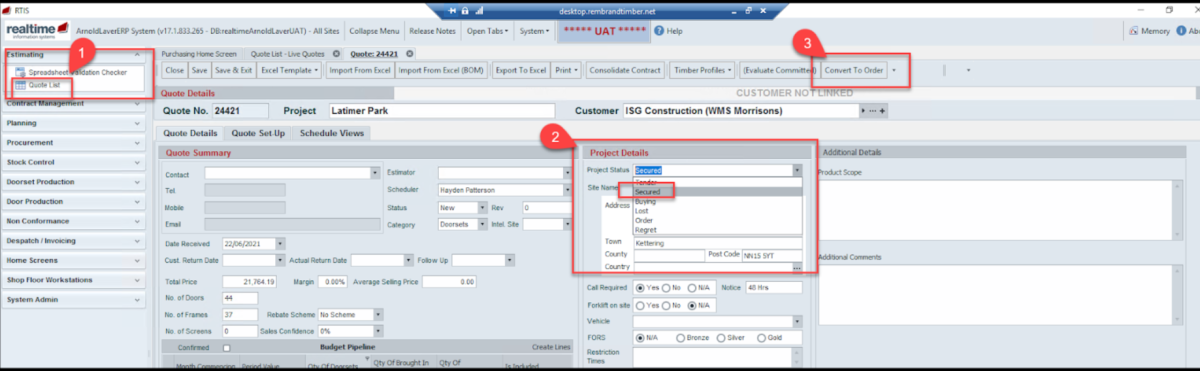

How to convert a quote to a contract

When a quote has been secured (won), it is then converted to and order the below steps are to be followed to complete this process.

Search for and open the quote which is to be converted to an order by selecting the estimating menu and select quote list.

How to raise a quote

Select the convert to order tab

New window opens which is the converted quote to a contract the contact has been given the next unique system generate contract number

Contract Management

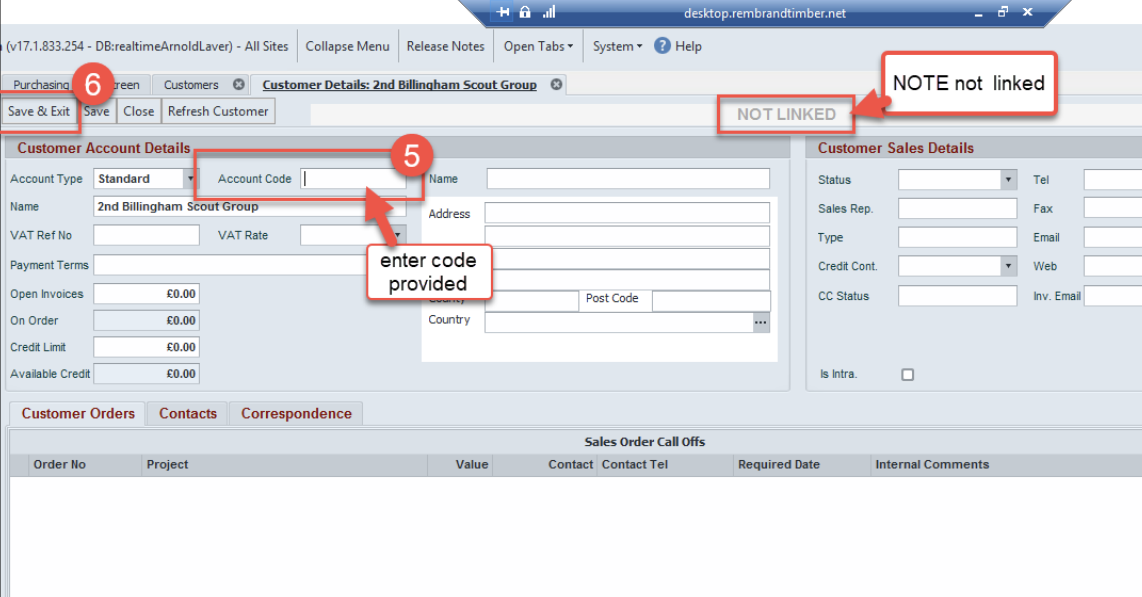

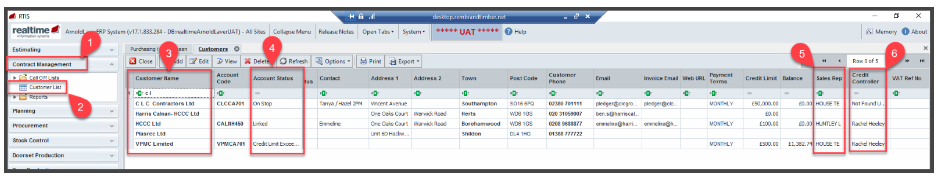

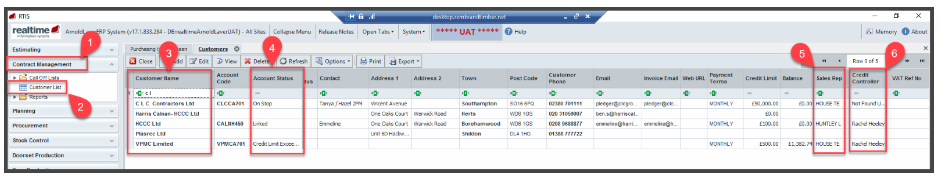

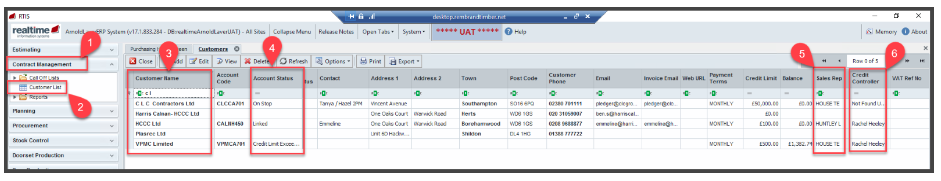

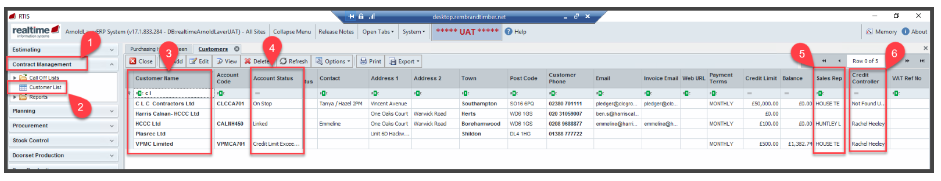

How to link a customers account

- When a new customer is set up accounts/credit control will email to say the account is now ready for use and is to be LINKED

- Follow the below steps to link the account, this will then allow contracts and calls off`s to be entered into Rtis

Take a note of the customer’s account number provided by accounts

Search in the account code field to see if the number has NOT already been used (if the account code has already been used report this by emailing rtissupport@nationaltimbergroup.com ) check step 3 before proceeding to step 4

Search for customer this is to ensure the account code as NOT got two entries

(If there are two entries for the customer report this by emailing rtissupport@nationaltimbergroup.com )

Allow ten minutes for this to activate this is due to a time delay between Rtis and NAV. – the refresh tab may need to be selected for the account to show as LINKED

How to convert a quote to a contract

When a quote has been secured (won), it is then converted to and order the below steps are to be followed to complete this process.

Search for and open the quote which is to be converted to an order by selecting the estimating menu and select quote list.

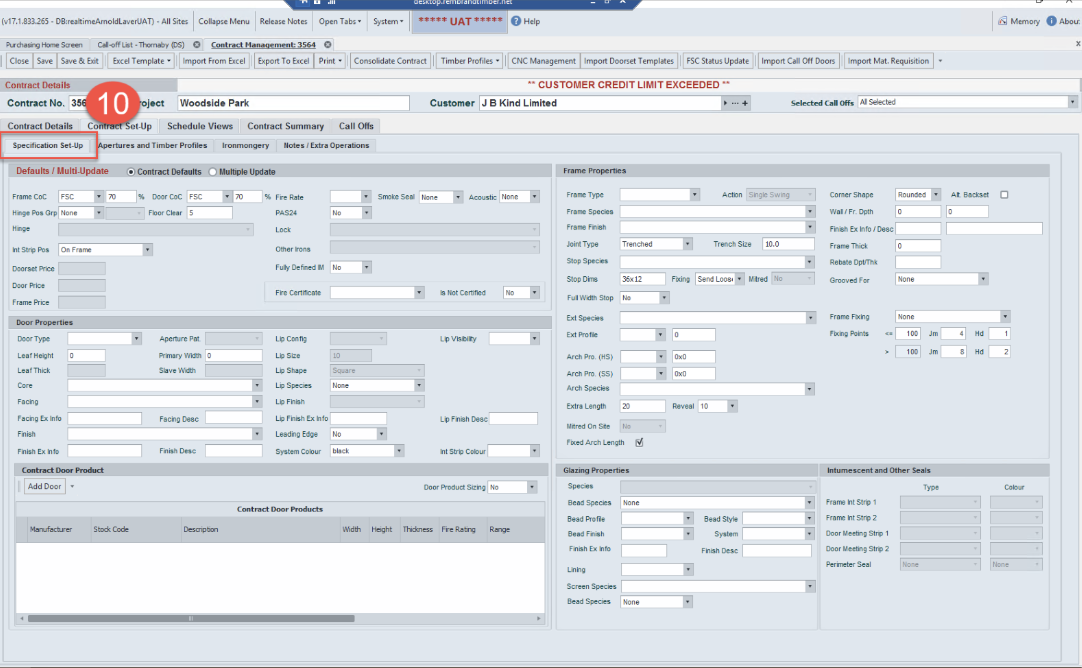

How to set up a new contract

When setting up a new contract ensure you have all the handover documents to hand and saved in the appropriate network area

From the contract management menu select call off list- and select your site

If selecting ALL SITES– a new pop up will appear asking which site, do you want to create the new contract in see image 1 (A and B)

Select the drop-down arrow next to add and select the type of contract

- Architectural

- Housetype/plots

Complete these fields

- Contract man is the scheduler

- BDM/Estimator enter their name or the salesperson name

- CoC Scheme select the correct scheme

- Intel Site select your site ( this may be auto populated , it is best practice to check)

Select the Customer Orders tab – this is where the customers purchase order is added

- Cust order No enter the purchase order number

- Date received - this is the date Intelligent doors received the order

- Select the + which opens in the shared network area

- Search for the purchase order and attach

- Select the … and view the purchase order

- Add any relevant comments

- Enter the value of the purchase order

Site details – enter the site name and full address including postcode –

- Call required – select the correct option as per the handover document

- Forklift on site – select as per the handover document

- Vehicle – select from the drop down as per the handover document

- FORS – select as per the handover document

- Restriction time – enter these in the free text box as per the handover document

Site contact – complete adding all contracts on the handover document

- Select the + to add a contact

- Role

- Name

- Telephone number

- Mobile

- Email address

- Main – select this against who is the site main contact

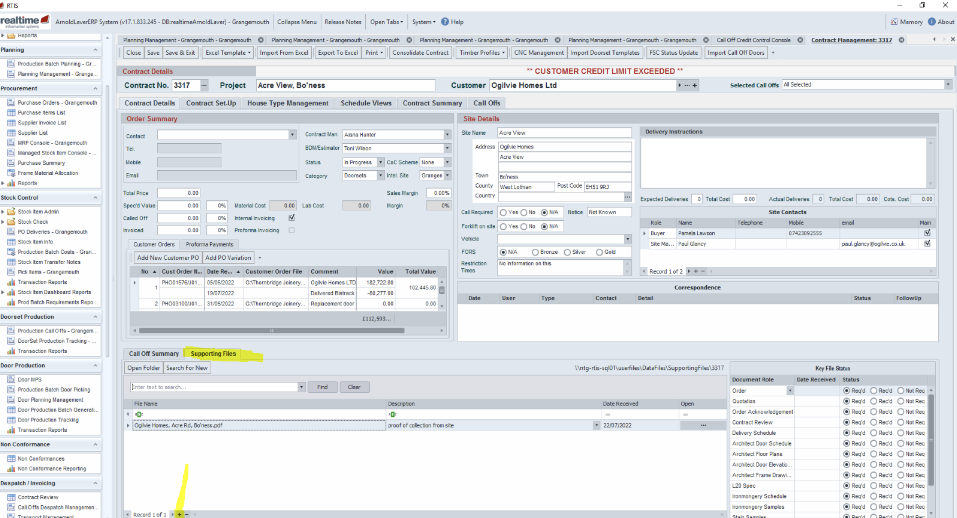

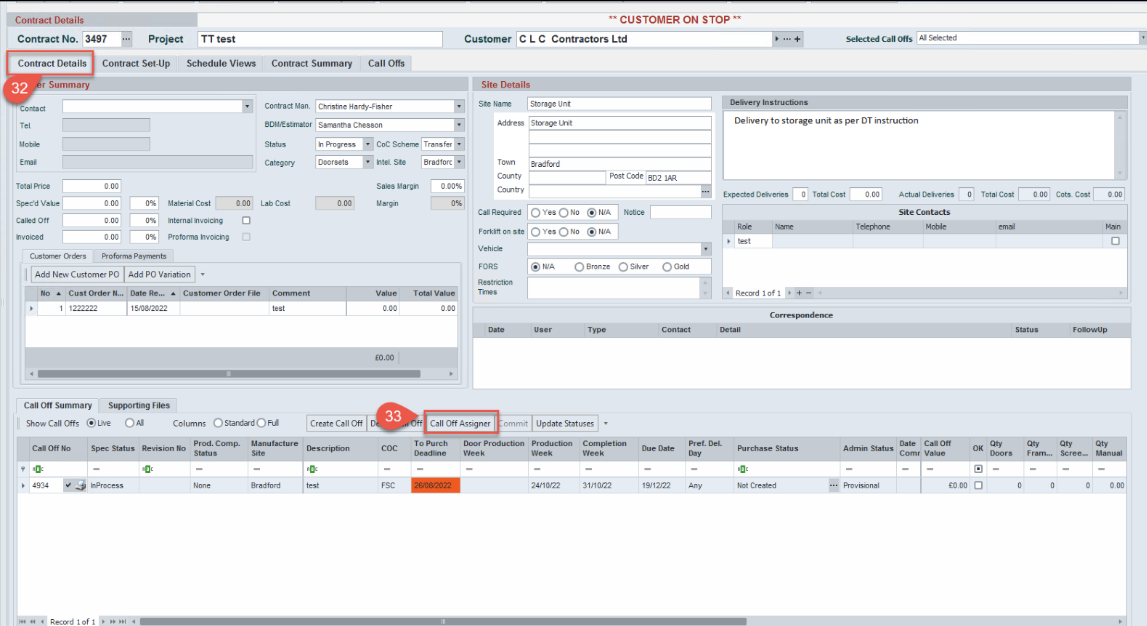

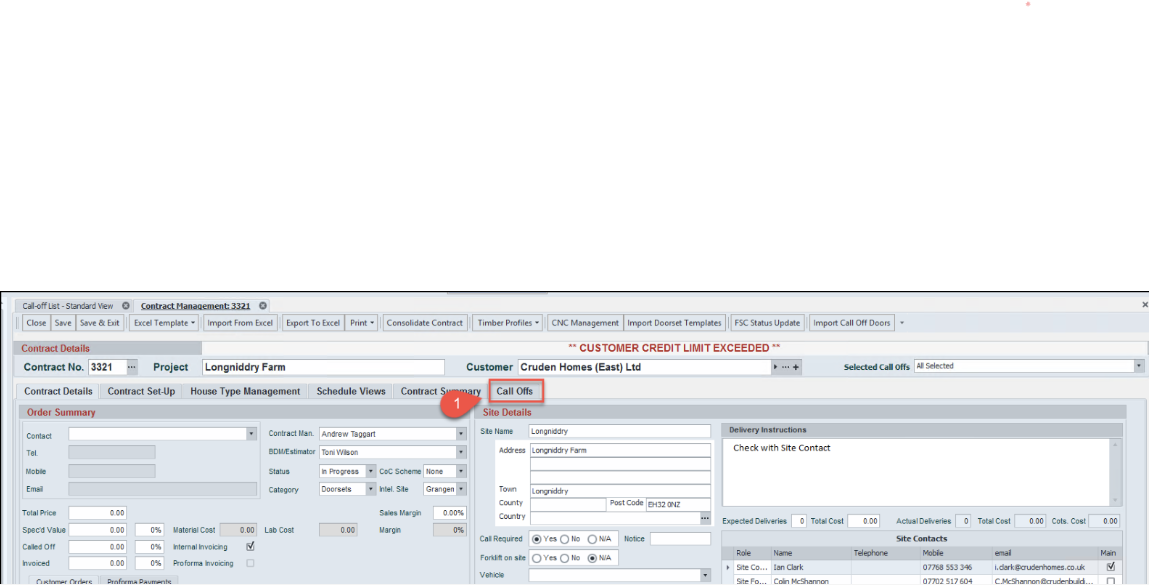

Customer on stop- this is a warning from credit control there are different levels of credit see image

To find out who the credit controller is follow these steps

- From contract management menu select customer list

- Search for customer

- View the credit controller in the credit controller column

The credit controller will need the following information

- Call off Number

- Copy of Purchase Order

- Value of Purchase order

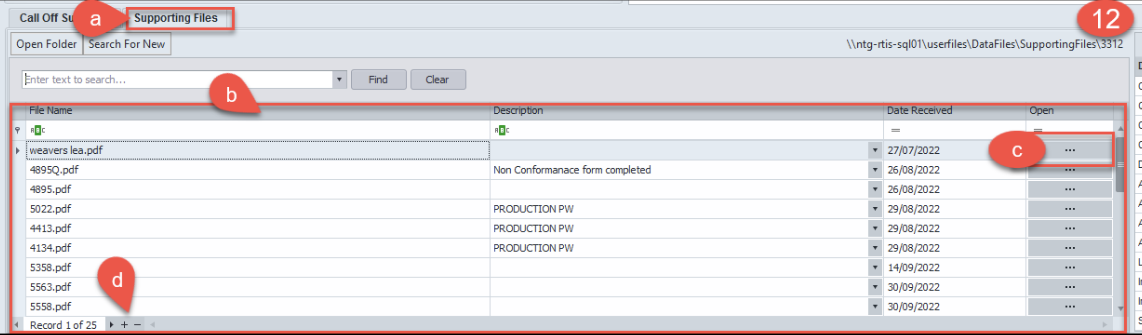

Supporting Files- here additional files can be added follow this link to the training documents 05.How To - Save and Add documents to the supporting files tab v1.docx

- Click on the supporting files tab

- This opens the view to see already added files

- Opens document

- Here is where you knew files

How to add a note to doorset spec

In Rtis/Realtime

Menu selected Contract Management ……………Topic from within Menu…Call off List….

Notes are added to communicate additional instruction to different departments, particularly special instructions for the production team as an example when using the below products, production will need a note adding. ** It is good practice to add all notes when first setting the contract up the same as is completed for ironmongery

- Heavy duty roller catches

- Flushbolts

- Sliding Doors

- Special Cuts

Search for Call off

New window opens

Select Contract set up tab

Select Notes and extra tab

Add a note

Contract note Number Field add a number 1

In the Description field enter topic here

Notes – add the exact detail request

Visibility select from drop down Who you want to see this

Save

Click back in description field, this generates a reference no

Back to House type Management

In doorsets notes field

Select +

Brings line up

Select from drop down note entered

Save

How to set up Ironmongery

Follow the below process steps to set up all ironmongery requirements for the contract

The handover document will detail all the ironmongery requirements

If unsure of standards, please refer to the Mondays.com board for information https://national-timber-group.monday.com/boards/762495528

Search in the search window, various ways to search, ideally the handover document will give the stock code

Work through the headings from left to right selecting what the customer has requested as per the handover document

Ensure the correct position is added for items that require this

- Positioning for a Lock – the standard position used is the centre line of the spindle

Save and exit

How to save and add documents to the supporting files tab

- Here are the steps of how to add documents to the supporting files tab within a contract

- Note *** it is essential that the documents attached to a contract are first saved in Sharepoint/Mondays.com otherwise no one else will be able to see the documents Lisa Dodds will confirm which documents are save in either SharePoint/Mondays lisa.dodds@inteldoors.co.uk

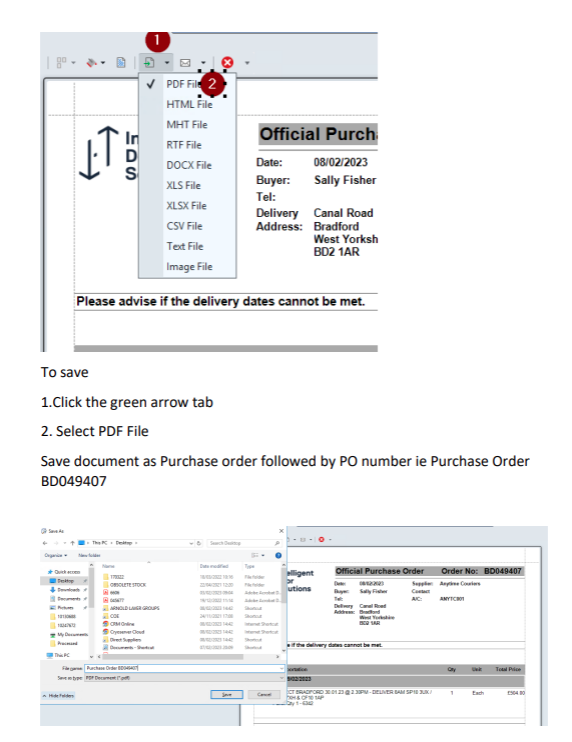

- Saving documents steps 1-2

- Attaching documents to the supporting files tab steps 3-10

Scan the paperwork to yourself

Save in Sharepoint/Mondays.com

Select call off list from the contract management menu

Search for call off

This expands the section, select the + from the bottom

This opens access to your folders

Search for your saved document which you have saved in either SharePoint or Mondays.com

Double click on the document you wish to attach

Add a description in the description field

- Example if attaching emails/customer comms – add brief description i.e.; “customer call off list “

- For production paperwork “ Production Paperwork “

How to create a call of using Architectural Selection

Open the contract the call off is to be created in

Select the correct CoC for the call off (this will be FSC/PEFC/Non certified) all except Grangemouth as no accreditation

Enter the lead times by selecting the correct date in the Production week column Individual site will have different lead times these will be agreed, and rules set up in Rtis to reflect these

If this calls off has a requested alternative delivery address complete this field refer to the full process steps in this link 46-How to Add an Alternative Address v1.1.docx

Save

Add the doorset/door/frame requirements

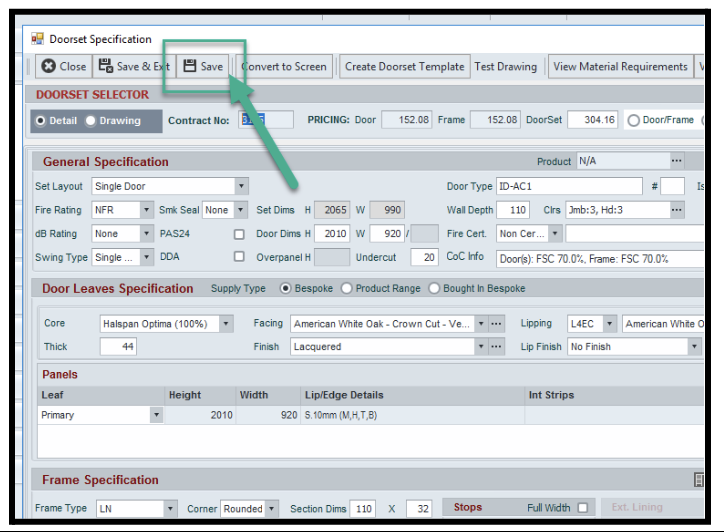

Door set Specification window now opens ready to input the specification required by customer – complete all relevant fields starting at the top

Doorset selector section here select either doorset or door/frame and enter the pricing details from the handover document

General Specification – complete all fields as per the handover document

- missing information from the handover document this will need to be obtained before proceeding

- For technical information refer to the technical standards are on Mondays.com board by following this this link https://national-timber-group.Monday.com/boards/762495528

- For additional technical support contact joanne.hardy@inteldoors.co.uk or david.hallam@inteldoors.co.uk

Doorset Notes This is where you can add your already set up notes into the doorset. This link is to the process document How to add a note to doorset spec v1.docx

Door leaves Specification – supply type is to be selected first

Product Range = Catalogue door from supplier i.e., Vicaima /Premdor

- Service option – are standard options that supplier offers

Select the … next to service options to make selections here

Bought in Bespoke = is a way to buy from a third party (only to be used in exception when Inteldoors cannot fulfil the requirements)

Frame Specification – In this section the intumescent strip information is displayed changes to colours are made here

Frame Comps and Arch Comps tabs – check correct entries pulled through amend any requirements as per the handover document – select the spy glass to view a sketch of the profiles see image 7

Ironmongery – here selection is made from the earlier set up of the ironmongery.

A reminder of how to set this up follow this link How to set up Ironmongery.docx

Additional ironmongery can be added by selecting the add iron item/add iron pack

A select add iron item

B select the … to add

By selecting the drawing, image you can view an image of the doorset which shows the hinge and vision panel positions

The Valid warning at the top of the doorset starts off as Red and it should turn to green upon completion of the doorset, if still red select the warning this will open a new window

This new window will detail what is causing the warning to still be red, these needs investigating and resolving before proceeding

- Check your entries

- Check the standards

- Request technical help

- Request help from the Rtis hep desk rtissupport@nationaltimber.co.uk link for how to use the help desk click here 5.How to – Get Rtis help-support-ask a question v1.docx

Once the valid/invalid warning is green, select the view material requirements tab this will go dark grey whilst Rtis checks all requirements, this can take a few minutes as the systems is checking the doorset.

When complete a new window opens any unspecified items will be highlighted in yellow, these need to be addressed before proceeding

- Check your entries

- Check the standards

- Request technical help

- Request help from the Rtis hep desk rtissupport@nationaltimber.co.uk link for how to use the help desk click here 5.How to – Get Rtis help-support-ask a question v1.docx

Assign to a call off

Items to be assigned will be highlighted in red in the tab check this is correct and select to assign to call off

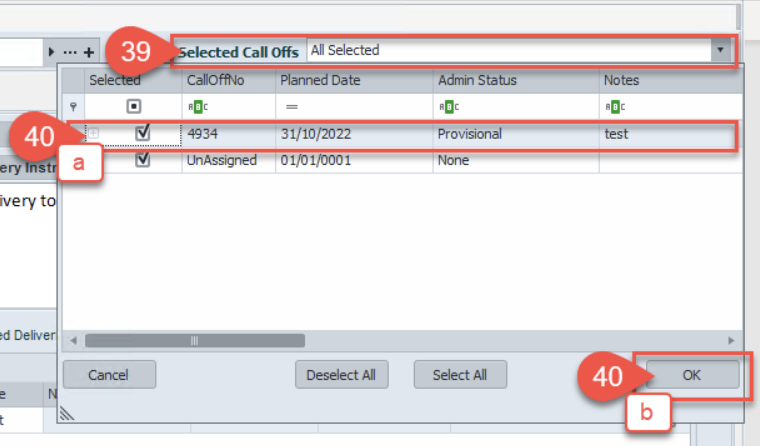

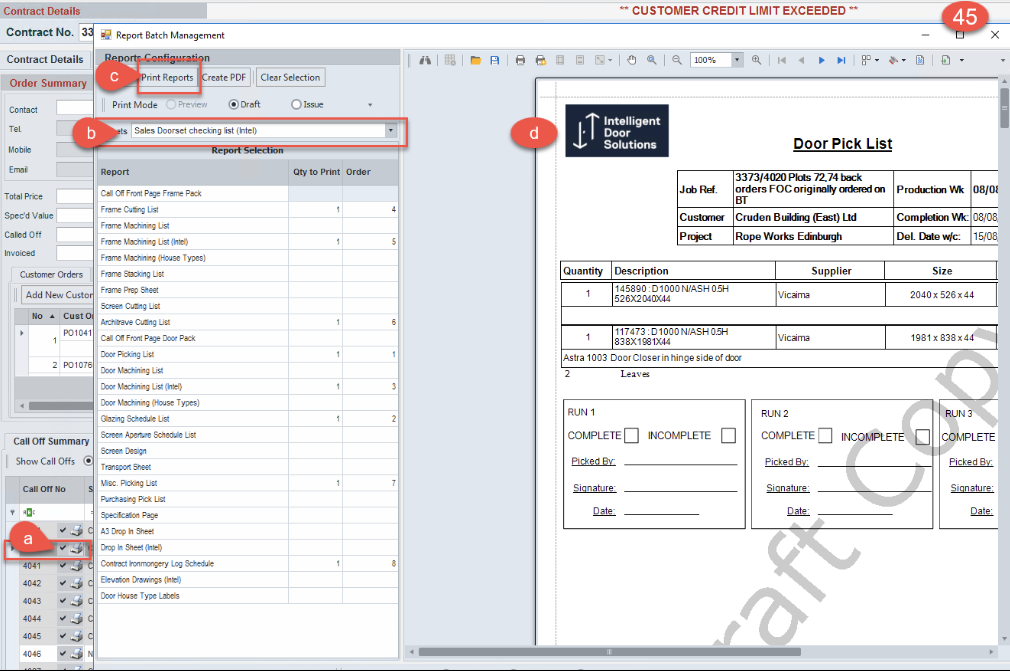

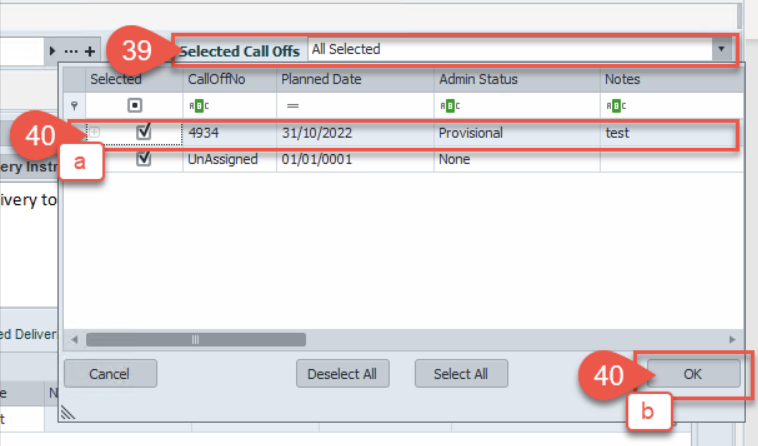

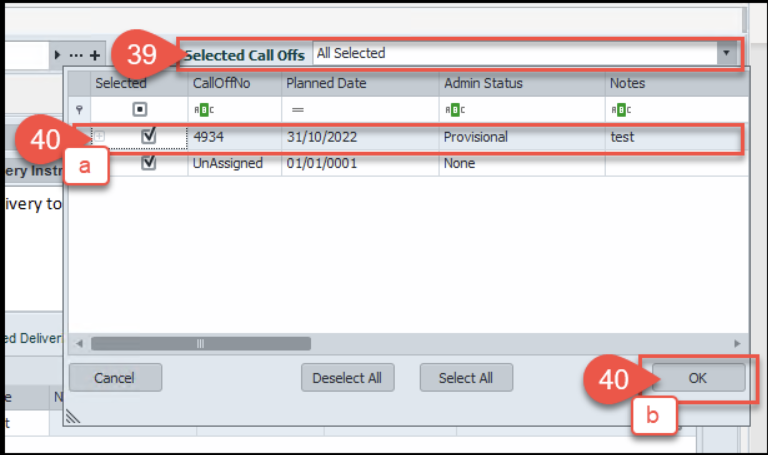

How to produce schedule to send to the customer

A. Ensure that you only Select the call off required for the customer (NOT unassigned)

B. Select ok

Window closes

a. Check the selected call off is correct

b. Select print,

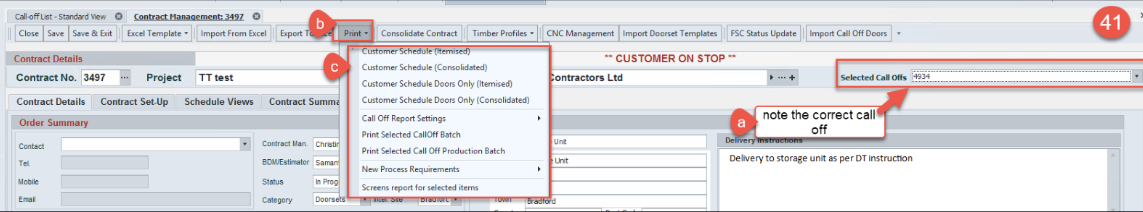

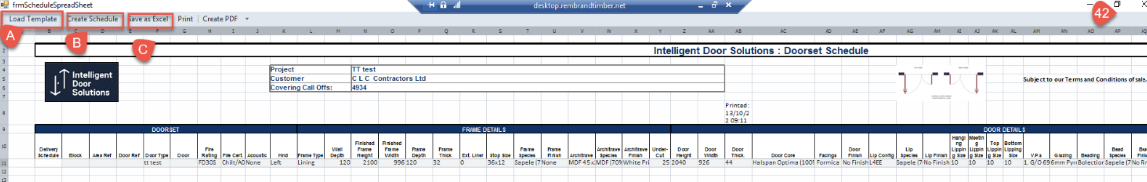

c. select the correct required schedule dependant on what is on the call off this will generate the schedule ready to send to customer

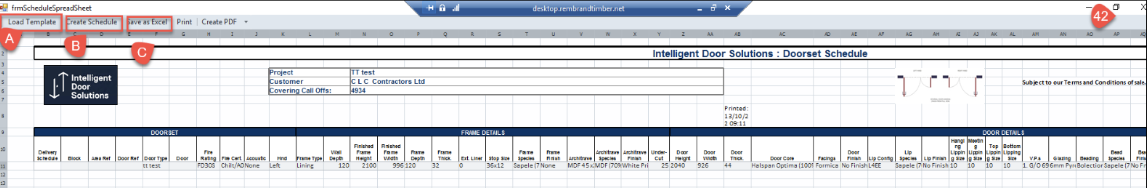

a. select load template

b. select create schedule

c. select Save as Excel this document and tidy up before sending to the customer for approval

Once the customer has confirmed the schedule is correct proceed to updating the purchasing status, reviewing the paperwork and committing the call off

From the call off line Select the … in the purchasing status, new window opens

a. click on the select all tab,

b. then select the regenerate selected tab,

c. message appears are you sure you want to recreate the purchase requirements click OK

d. message will appear update completed Select OK

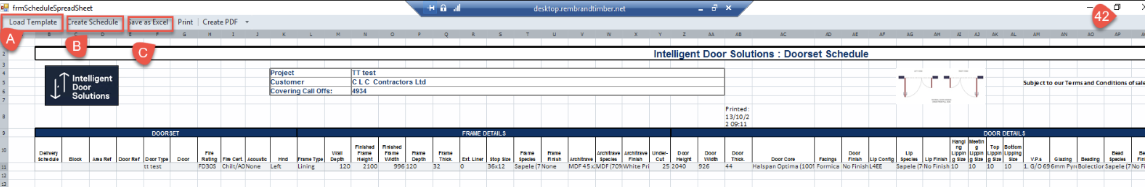

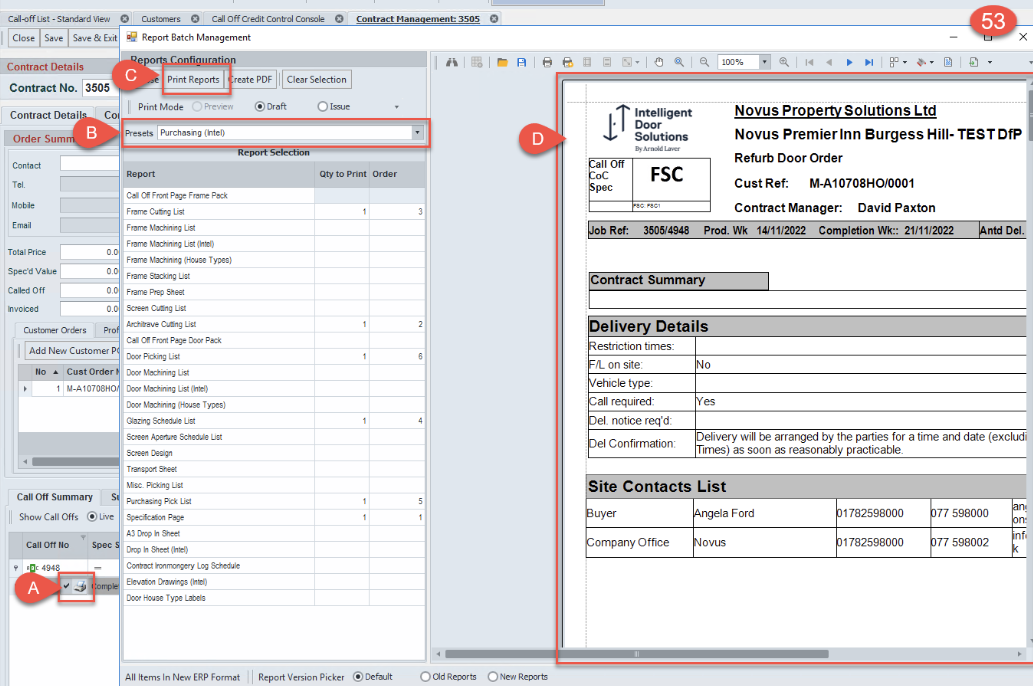

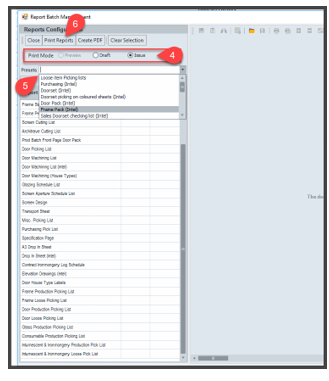

From the call off line

- select the printer icon

- select Sales Doorset checking list (intel) from the pre-sets drop down

- select print reports

- paperwork PDF appears, view this here checking what you have entered is all appearing correctly

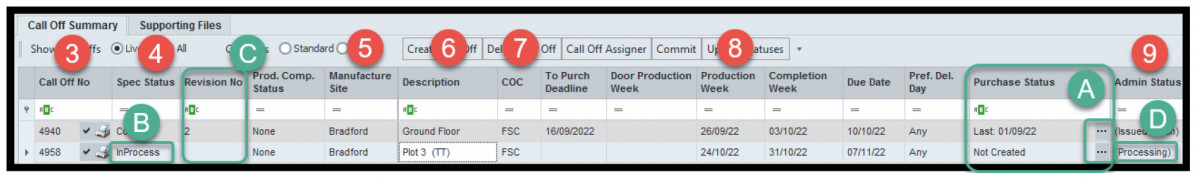

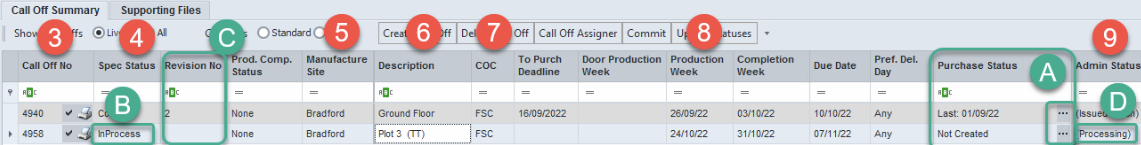

How to commit

Ensure you have clicked in the correct call off, Change spec status to complete in the call off line

If the commit tab is NOT active hover over it and the reason it is not active shows these can be

- Customer over credit limit

- FSC

- Unspecified items if unspecified items follow the below to locate where in the call off these items are

a. Select schedule view

b. Ensure viewing the required call off

c. Select Select visible tab

d. Select Mat Reqs tab this now runs a check to locate where the unspecified items are

e. Pop up window confirms it has found errors these are highlighted in red

Open the doorset and correct the errors identified

Call off line is now a darker grey and no further changes can be made commit tab changes to being greyed out

Now release the paperwork for printing by clicking in the revision No column and release paperwork

Save

The production paperwork will be printed and given back to Scheduler for a final check before handing over to production for manufacture

How to create a call off using Housetype selection

Before starting a call off checking and preparing the handover documents will save time, this ensures you have the relevant information to enter Rtis. Below are a few contact suggestions for missing information

- Thoroughly check the handover documents, communicate with the estimator and salesperson for clarification or missing information

- There may be a need to communicate with the customer to obtain some details

- For technical information refer to the technical standards are on Mondays.com board by following this link https://national-timber-group.monday.com/boards/762495528

- For additional technical support contact joanne.hardy@inteldoors.co.uk or david.hallam@inteldoors.co.uk

If you have any doubt about information or products, please DO NOT guess ask for help

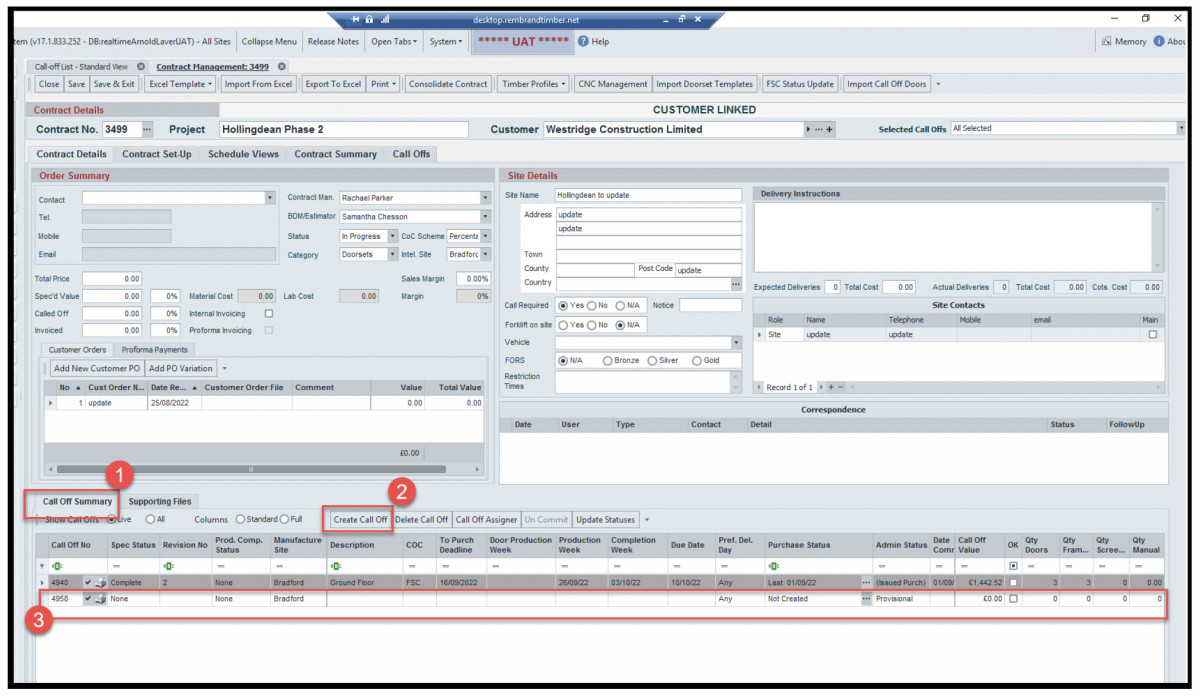

Creating a call off

Open the contract the call off is to be created in

Select the correct COC for the call off (this will be FSC/PEFC for all except Grangemouth as no certification in place now)

Enter the lead times by selecting the correct date in the Production week column

Individual site will have different lead times these will be agreed, and rules set up in Rtis to reflect these

If this calls off has a requested alternative delivery address complete this field refer to the full process steps in this link 46-How to Add an Alternative Address v1.1.docx

Save

Add the doorset/door /frame requirements

Select House type management tab

Select add a house type this generates a blank house type

- Replace (new house type) with the actual house type name

- Replace (new plot) with plot number /name

- As/opp this is reference the handing the first plot is known as the AS ( as the drawings) subsequent plots are to be selected as per customers’ requirements for the plot select here from the customers drawings

- Call off column will be populated once this plot is assigned to a call off

- Desp. Column give the despatch status of the call off

Door set Specification window now opens ready to input the specification required by customer – complete all relevant fields starting at the top

Doorset selector section here select either doorset or door/frame and enter the pricing details from the handover document

General Specification – complete all fields as per the handover document

- missing information from the handover document this will need to be obtained before proceeding

- For technical information refer to the technical standards are on Mondays.com board by following this this link https://national-timber-group.Monday.com/boards/762495528

- For additional technical support contact joanne.hardy@inteldoors.co.uk or david.hallam@inteldoors.co.uk

Doorset Notes This is where you can add your already set up notes into the doorset. This link is to the process document How to add a note to doorset spec v1.docx

Product Range = Catalogue door from supplier i.e., Vicaima /Premdor

- Service option – are standard options that supplier offers

Bought in Bespoke = is a way to buy from a third party (only to be used in exception when Inteldoors cannot fulfil the requirements)

Frame Specification – In this section the intumescent strip information is displayed changes to colours are made here

Frame Comps and Arch Comps tabs – check correct entries pulled through amend any requirements as per the handover document

Ironmongery – here selection is made from the earlier set up of the ironmongery.

A reminder of how to set this up follow this link How to set up Ironmongery.docx

Additional ironmongery can be added by selecting the add iron item/add iron pack

A select add iron item

B select the … to add

By selecting the spy glass and the drawing, images can be viewed of what the doorset will look like

The Valid warning at the top of the doorset starts off as Red and it should turn to green upon completion of the doorset, if still red select the warning this will open a new window

This new window will detail what is causing the warning to still be red, these needs investigating and resolving before proceeding

- Check your entries

- Check the standards

- Request technical help

- Request help from the Rtis hep desk rtissupport@nationaltimber.co.uk link for how to use the help desk click here 5.How to – Get Rtis help-support-ask a question v1.docx

Once the valid/invalid warning is green, select the view material requirements tab this will go dark grey whilst Rtis checks all requirements, this can take a few minutes as the systems checks the call off

When complete a new window opens any unspecified items will be highlighted in yellow, these need to be addressed before proceeding

- Check your entries

- Check the standards

- Request technical help

- Request help from the Rtis hep desk rtissupport@nationaltimber.co.uk link for how to use the help desk click here 5.How to – Get Rtis help-support-ask a question v1.docx

Once the first doorset has been created house type management has several features these features, and tabs are explained below

- Add House Type – select this to add a housetype

- Duplicate HT – by selecting this tab the house type will duplicate

- Duplicate HT from order – this will duplicate a house type from a different call off see steps 33-39

- Delete HT – this will delete the selected House Type

- Add Plot – adds plots to the selected house type

- Delete a plot- this will delete the plot selected

- Add new doorset - by selecting this tab a new doorset will be added

- Duplicate a door set – when this tab is selected it will duplicate the doorset

- Delete a doorset -if required

Duplicate HT from order

Note the contract number and call off number to be duplicated

Select the duplicate HT from order tab

From the contract No field select the drop-down arrow

This opens new window - search here for the contact and select open

This then populates all the call offs into the scree

Locate the call off required and click on the select grey button

This then add this housetype to your current contract

Assign to a call off

Items to be assigned will be highlighted in red in the tab check this is correct and select to assign to call off

How to produce schedule to send to the customer

- Check the selected call off is correct

- Select print,

- select the correct required schedule dependant on what is on the call off this will generate the schedule ready to send to customer

- select load template

- select create schedule

- select Save as Excel this document and tidy up before sending to the customer for approval

Once the customer has confirmed the schedule is correct proceed to committing the call off

How to commit

The commit button will now be active select this it will go dark grey whilst it processes to committed. Message appears to confirm committed

Call offline is now a darker grey and no further changes can be made commit tab changes to being greyed out

Click on the

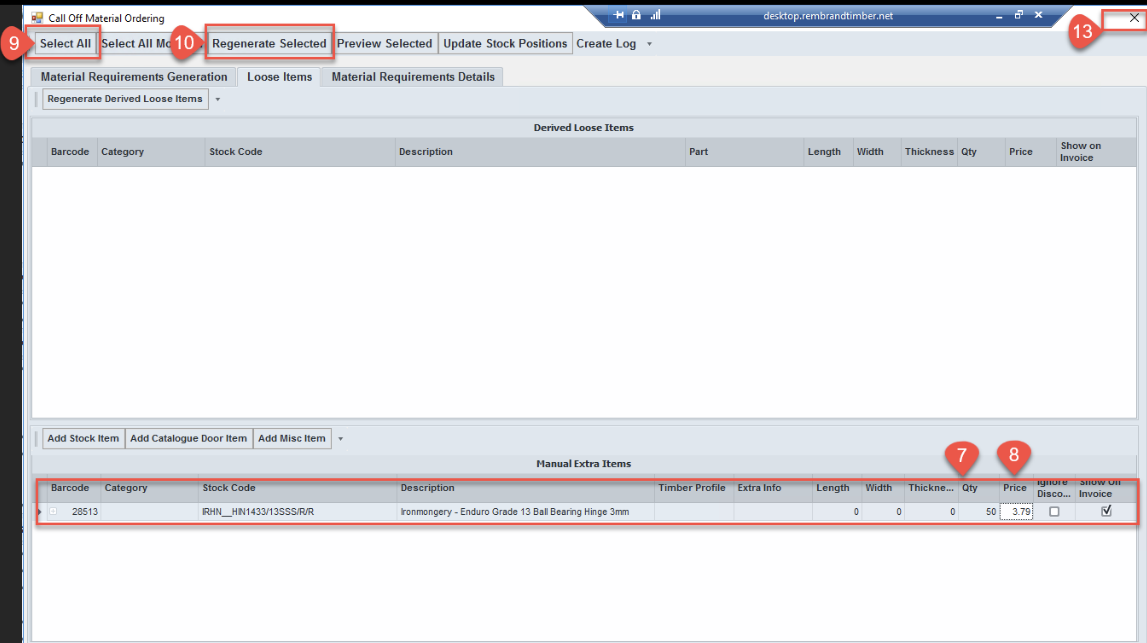

- click on the select all tab,

- then select the regenerate selected tab,

- message appears are you sure you want to recreate the purchase requirements click OK

- message will appear update completed

- select ok

Now release the paperwork for printing by clicking in the revision No column and release paperwork

Save

Check and review the Sales Doorset checking list (intel) pack paperwork

How to correctly enter a FD30`s smoke seal to doorset spec

In Rtis/Realtime

Menu selected Contract Management ……………Topic from within Menu…Call off List – House type management - doorset

These steps from within the doorset spec window will ensure that the correct smoke seal is selected whilst entering the detail in the general spec section of the doorset

Select the fire rating from the drop down arrow

Select FD30s

In the SMK seal box select from drop down arrow Fin

Navigate to the right hand side of the window inline with the frame specification section

Select frame comps

Select Int Strip

Change Jamb Primary in drop down to 15 x 4 Pyroplex offset flipper

Go to Jamb secondary in drop down and change to 15 x 4 Pyroplex offset flipper

Select head in drop down and change to 15 x 4 Pyroplex offset flipper

Save

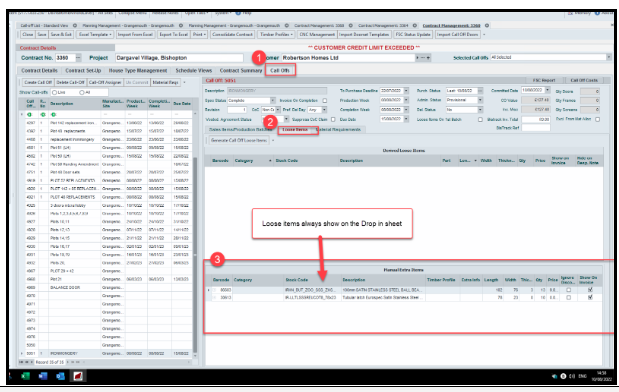

How to create a loose item

A loose item is a product that does not need manufacturing such as.

- A door only

- Ironmongery

This is created from the call off line by following the below steps.

Create a new call off in the normal way

If more items are required repeat the above steps until all loose items have been added

Pop up window appears asking are you sure you want to recreate purchase requirements select OK to continue

A new pop-up window appears after a few seconds saying update complete OK select ok to continue

When a call off is to be delivered direct from supplier to customer

Select the drop-down arrow in the admin status column and select Direct Dly this will be clear to purchasing – planning and transport that the supplier is delivering these goods

When the call off is free of charge for the customer

If this item is authorised as free of charge for the customer tick the FOC box this then does not affect the credit status of the call off credit control do not see a call off that has this ticked

When a call off is of high priority and requires purchasing to act upon straight away

- In the description column enter AFTERCARE 12345(aftercare related no)

- Once call off complete email purchasing @inteldoors.co.uk /flag to your onsite purchaser that this is urgent

- in subject field of email write aftercare

- in email enter call off number and request urgent attention

- if your onsite purchaser is not available by emailing the purchasing inbox this will be pick up by a member of the wider purchasing team as a matter of priority

How to Import Doorset from template

- Templates are used when regular repeat orders and specification for a door type are the same, this saves schedulers time allowing call off`s to be processed more efficiently.

- Template set up can be requested by logging the request at rtissupport@nationaltimbergroup.com

- This feature is for Architectural orders as the copy feature in housetype is the same principle

This opens a new window which lists all the templates Search for the template required and click on select and click done

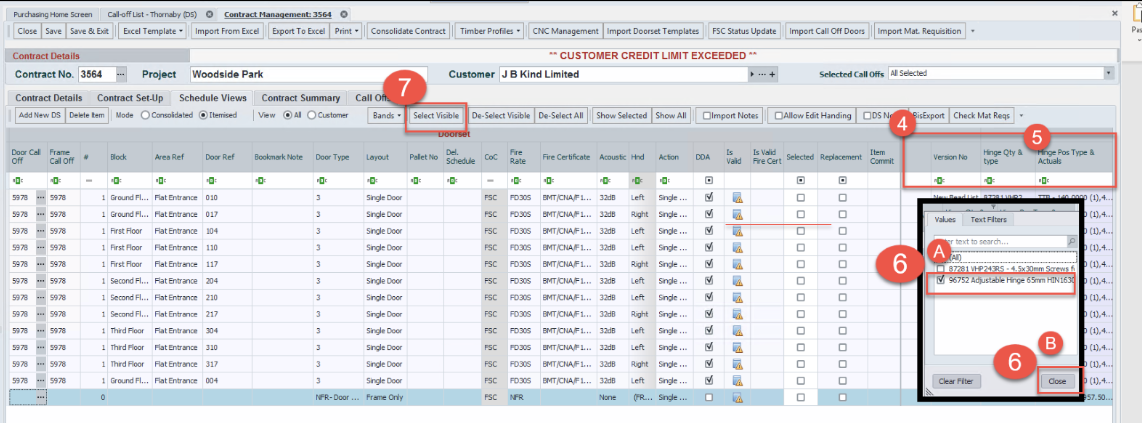

How to Globally make changes

Global changes allow changes to be made to the whole contract without having to open and amend every doorset. Follow the below steps to complete this process, the example used in this document is to change the ironmongery, the principle is the same when making other global changes

*** care must be taken here as changes here will change every doorset***

- Help can be requested by contacting rtissupport@nationaltimbergroup.com

Select the filter feature from within the header column, this details what is available to change

Select multiple updates which opens new window - here is where the qty`s in step 8 should match - continue to make the global changes

- Global changes can only be made in areas detailed in this screen

Go back to schedule view and check the changes have been made

- In step 5 the filter was selected to what was to be changes

- Remove this filter which will reveal the changes made

- Using the de – select all tab and show all tab will reveal all

Areas to double check

- Remove the filter or de select all and show all

- Check hinge column has changed

- Check QTY`s correct

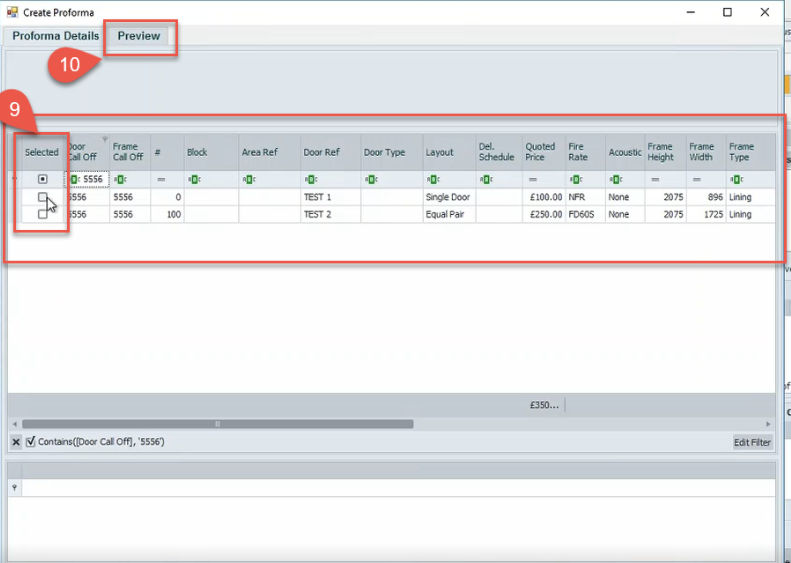

How to Create a Proforma Invoice

Proforma payments are taken from customer who do not have a credit account, below are the process steps that are required to create this type of order

Create the call off in the usual way, after assigning products to the call off continue with steps 1 to 15

Select the … in the in the proforma window cell this generates the next proforma sequential number

This opens a new window showing detail of all the product on the proforma, search for the call off you have just added

Select the spy glass document this will open the actual PDF this is then saved in project folder ready to send to the customer

What to email to customer?

- PDF of proforma invoice

- State clearly on email asking customer to notify scheduler once they have made a payment

When the customer confirms payment has been made contact Tom Smith in credit control will confirm this has been paid and release the order for scheduler to proceed

Proceed to committing the order and updating the statuses in the call off

How To - Un assign a call from a batch to re assign on to another Batch

Select visible to unassign tab and select the correct selected based upon what is on the call off

- Doorset

- Doors

- frames

How to add screens to an Architectural call off

- Screens are added by trained and experienced schedulers Joanne Hardy has a list of authorised schedulers to complete this process to find an authorised scheduler please contact joanne.hardy@inteldoors.co.uk

- This link is a video demonstrating the process for adding screens https://youtu.be/CTpt1B3e3i8

In preparation for following the video create call off as normal, from within the doorset specification once the frame specification has been entered , select the convert to screen and follow video

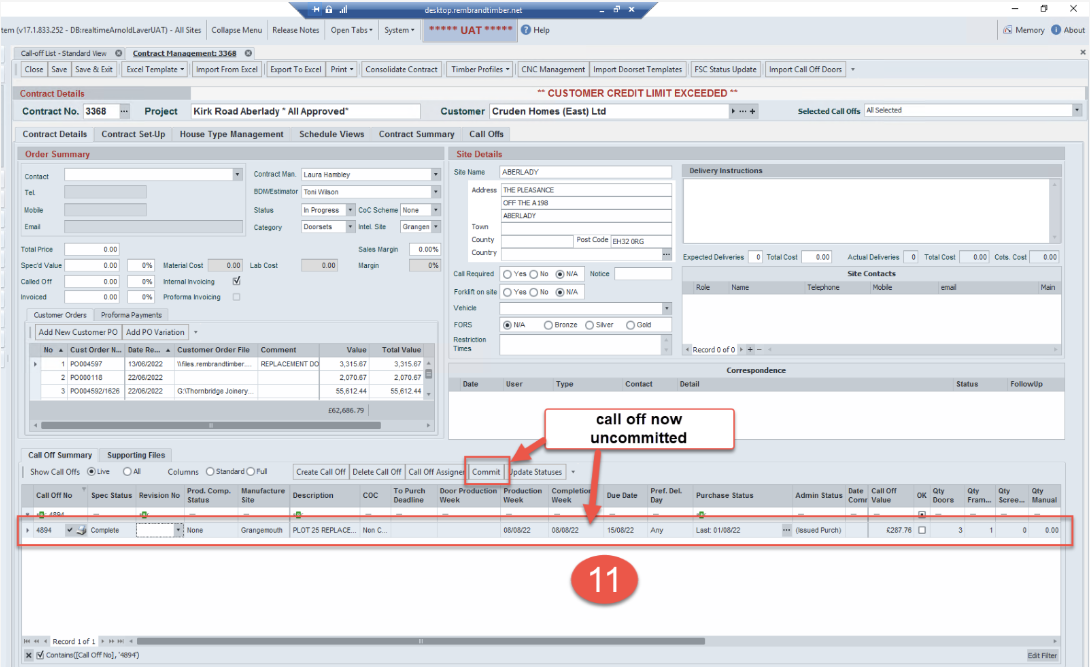

How to Un commit a call off

Only authorised persons can uncommit a call off. Before un committing a call off it is important to check the admin status

- if the status is at issued to purchasing, purchasing need to be communicated before any changes are made to the call off

- Status is at Issued to the factory - it is essential that the paperwork is retrieved, and that factory and purchasing are communicated with before any changes are made

How to view the Admin status of a call off

How to Un commit a call off

Select the call off ***note here the…

- Revision status column this as a number which states how many times there has been revisions made to the call off

- Un Commit is greyed out which means until the paperwork has been recalled the option to Un Commit is not possible

Select the active uncommit tab

Note ***

- The revision No column no longer has a number in the field

- The Un Commit tab is now active

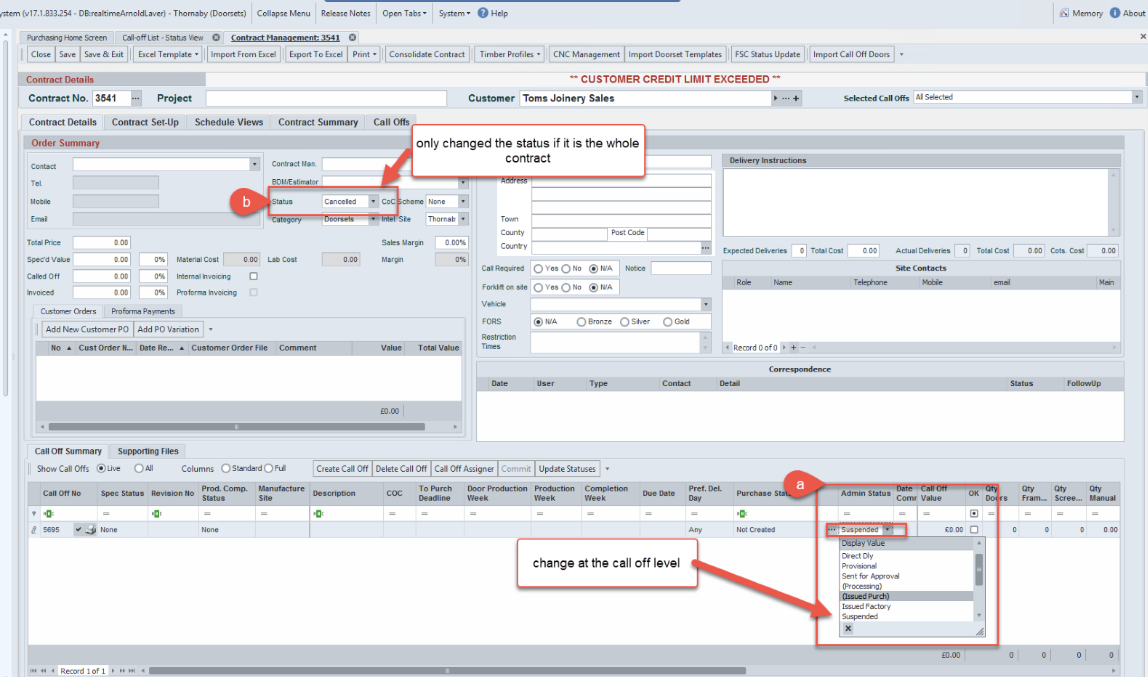

How to Suspend a Call Off

Call off and contracts cannot be deleted in Rtis. The steps below show how.

- A call off can be suspended

- How a contract can be cancelled

Suspend a call off

Search for the call off that is to be suspended

Select Save

How to cancel a contract

A contact can ONLY have a status of cancelled if ALL the call off`s are all suspended

Select Save and exit

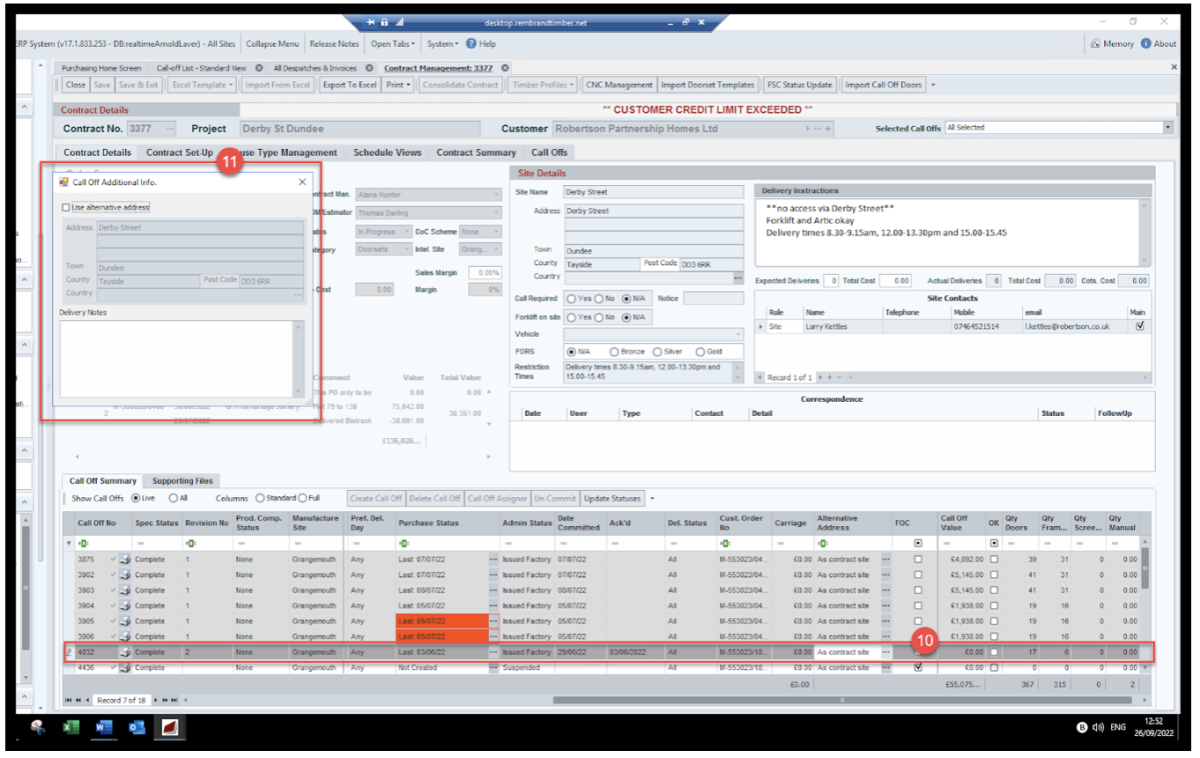

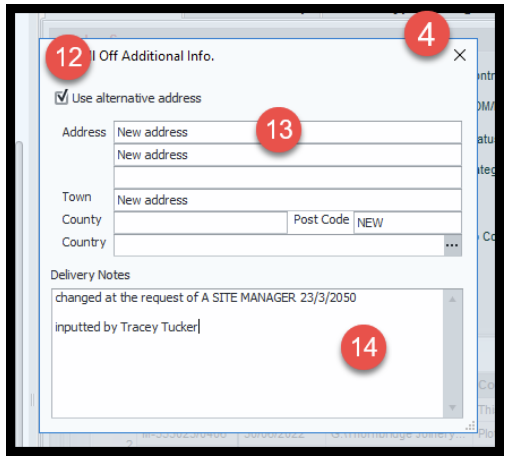

How to add an Alternative address

Before changing the address, it is essential that the status of the call off is checked the below steps cover all status

Admin status at issued to purchasing covering Direct deliveries

Unless this is a direct delivery changing the delivery address does not affect purchasing

If this call off is a direct delivery, speak to purchasing before any changes are made to the call off

If purchasing has not placed the purchase order to the supplier proceed to steps 10-16

Admin status at issued to factory

Recall and replace the transport sheet that has been issued to the factory

Communicate with factory to let them know that the delivery address is being changed and to destroy the current transport sheet in the production pack

Communicate with team that print the production paperwork to let them know the below.

5.1- Changes are being made to the delivery address

5.2- Once you have changed the address, inform team who print paperwork that the NEW transport sheets are ready to be reprinted and taken immediately to the factory

Once step 5.1 is complete proceed to change the delivery address by following steps 10-16

Despatched but NOT delivered or invoiced

Recall and replace the despatch Note and transport labels

- Communicate with transport to let them know that the delivery address is being changed and to return the current despatch note

- Communicate with the factory to let them know that the call off will need its transport label changing due to an address change

- Communicate with the team that creates the despatch note that the address change is to happen

- Once you have changed the address, inform team who print paperwork and who create the despatch note that the NEW documents are ready to be reprinted and taken immediately to Transport and factory

Once the above communication has taken place proceed with making the address changes by following steps 10-16

Invoiced status

Once a call off has been invoiced a delivery address CANNOT be changed if the goods are to be returned and re delivered follow the returns process

How to change a delivery address

In the delivery notes field include details of who requested the change and who made the amendments

Close the window by selecting the X

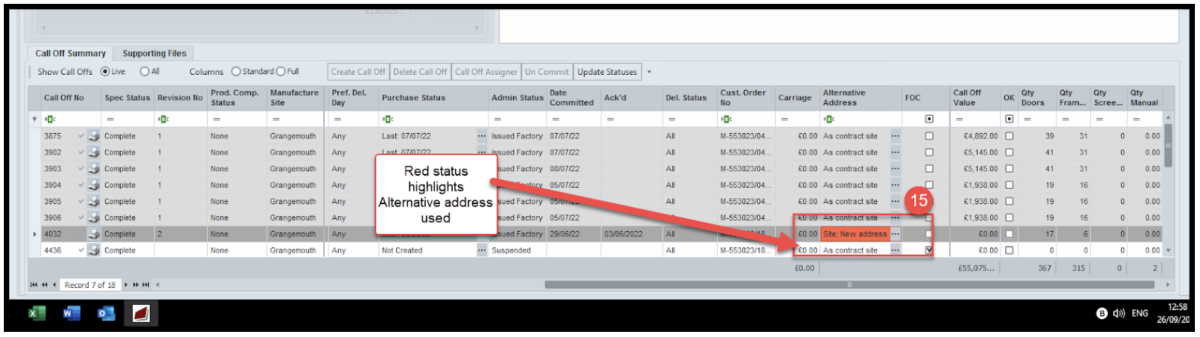

Check the alternative address column this should now be RED and read site New Address, save and exit the call off

Inform Paperwork/despatch/factory/transport teams that the address is now changed in the call off and that the relevant new paperwork can be printed and used straight away ensure all old paperwork is collected and disposed off

Order Type what paperwork to print -Grangemouth Process

Type of order |

What paperwork to print |

Loose Items can Include …

|

Show as loose items which is only seen on Drop in sheet |

Architraves |

Architrave cutting list |

Door Only |

Select House Type ( doors only) |

Frames Only |

Select House type (Frames only) |

Doorset |

Select House Type ( Doorsets) |

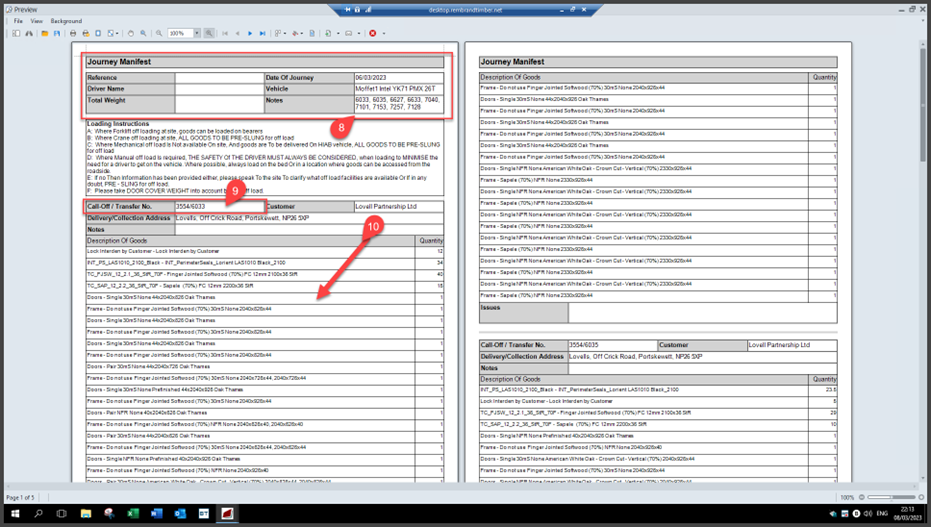

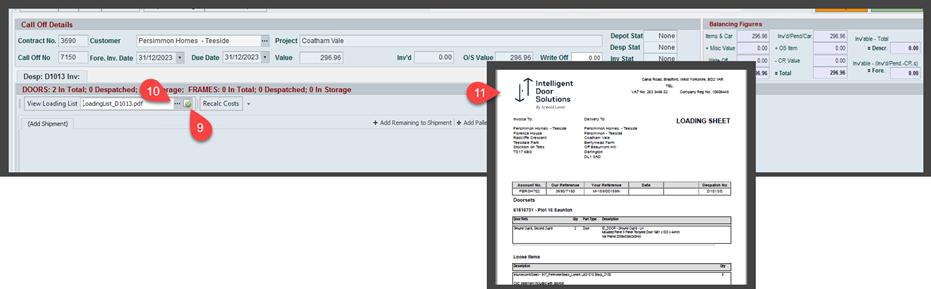

How To - Print production paperwork using doorset printer button

Menu selected…contract management………Topic from within Menu……call off list

Search for call off and open selecting the … before proceeding to check at call offline at the very far left for the total number of doors, this will enable you to print the correct number of pallet labels – make a note of the numbers

Select call off tab

Ensure call offline is high lighted

Before printing check for Loose items select the Loose items Tab (see screen shot 1 below)

If there are loose items these will be shown here – ensure when printing that the drop in sheet is printed as this is the only place in the paperwork where these are seen

Select the printer icon next to Doorset this is far right – note we never use door

New window opens

Ensure issue button is selected this will ensure paperwork does not have draft copy on

Select from drop down arrow doorset house type for doorset this is right at the bottom of the selection

If doors only select doorpack housetypes

If frames only select frame pack housetypes

When a call off is for ironmongery only or loose items – ensure that the Drop in sheet is printed this ensures production see all requirements

The paperwork selections are now auto populated deselect labels if selected

- Labels must be printed separate from the selection on the right-hand side of screen

Ensure House type Drop-in sheet is selected and always printed. Loose items are always on the last page of the Drop in sheet

Select issue from the print mode

Select print reports tab this generates the paperwork – select the correct printer and ensure the printer only prints single sided and print and close window

Print the house type labels separately from the right-hand side of the screen by clicking on the + button this generates the labels

Select the correct printer - select two copies for door sets – select tray 2 from the printer source area

Prepare the pack for production in the following order

- Front address sheet ensures that there is enough for each pallet and only one plot per sheet

- Door pick list

- Door machining list

- Drop in sheet

- Misc pick sheets

- Door labels

In a sperate clear pocket

- Frame machining

- Architrave

- Frame labels

- Paperwork handover sheet

- Loading sheet

Place paperwork in clear envelope red for a screamer white any other with a label with the date and day on

Pass to sales support person to check – then hand to Planning (SW)

How to View credit status and get an order released by credit control

In Rtis/Realtime and Manual via email

Menu selected Contract Management ……………Topic from within Menu…Customer List….

The below steps will show you what the credit status of customer is and who the credit controller is these septs are used when entering a new contract if the first page of the contract set up has a credit red warning follow the below steps before proceeding with sending Material schedules that the BDM send to the customer

- Step A - is view credit status and who is the credit controller

- Step B - is the manual process for content on the email to credit controller

How to view credit status and who is the credit controller

manual process and content on the email to credit controller

Email credit controller

Copy in BDM

In subject matter type the following:

- Customer name

- Contract number

- Call off number/s

In the body of the email include the below:

- Call off dates

- Ask for order to be released

Set a reminder flag for 48 hours after sending email to chase:

- Select follow up flag from top tool bar of email

- Select add reminder

- Select a date to be remaindered 48 hours away

- Adjust the time by selecting a time from the drop-down arrow

- Click OK

C - View call off on credit hold and export to excel

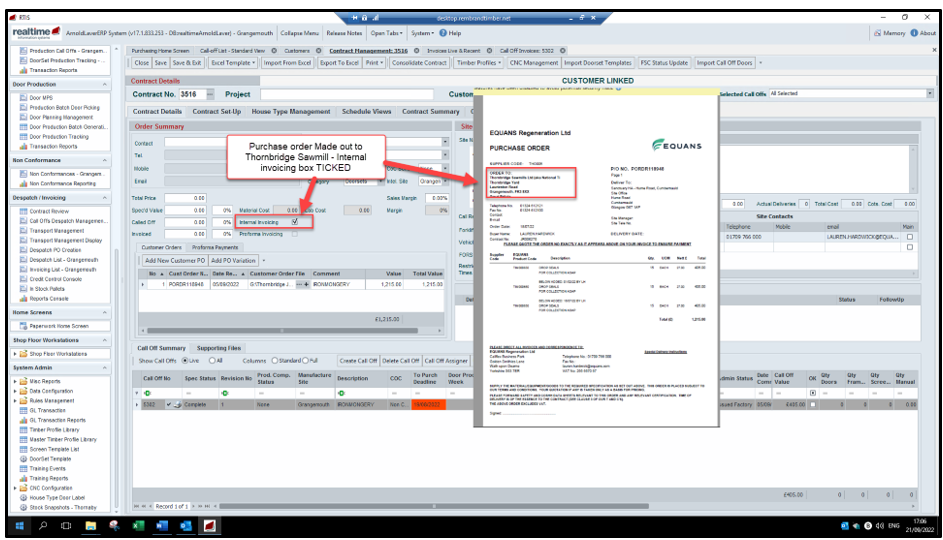

How to use Internal Invoicing Box Grangemouth ONLY

The internal Invoicing tick box is a way to flag to accounts whether the customer receives an invoice from Thornbridge sawmills or Arnold laver.

- Box ticked means that the purchase order the customer has supplied is made out to Thornbridge Sawmill

- Box unticked means the purchase order is made out to Arnold Laver

It is extremely important that great care is taken when creating contracts and receiving purchases orders. there CANNOT be a mixture of Thornbridge purchase orders and Arnold Laver purchase orders on one contract.

If a customer has started to issue all new purchase orders made out to Arnold Laver a new contract must be set up and the internal box NOT ticked

EXISTING CUSTOMER

Check if the internal invoice box is ticked or not

If ticked any new call offs must have Thornbridge sawmill purchases orders

- If the new PO is made out to Arnold Laver, then a NEW Contract must be set up ensuring the internal invoice box is NOT TICKED

If the internal invoice box is NOT TICKED, then the call off must have PO `s made out to Arnold Laver

Contract Delivery

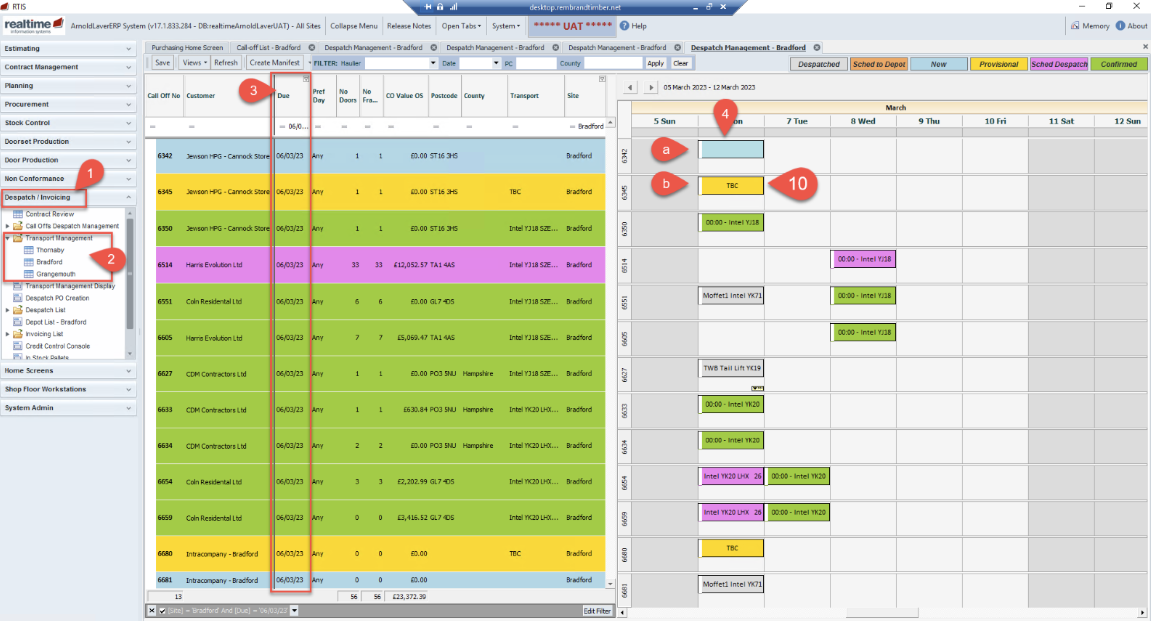

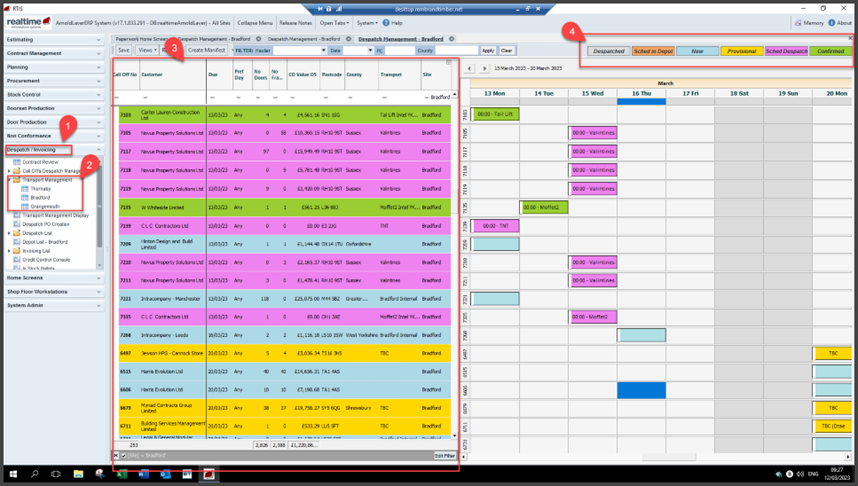

How to View delivery dates in Transport

- This view shows exact status transport are at with a call off

- Communicate in the normal way with transport should clarification is required, or the customer is requesting changes to be made

The right-hand side of the screen will show the exact status as per colour coding

a. Blue = New – customer has not yet been contacted to book in for delivery

b. Yellow = Provisional – customer has been contacted by contract delivery and has confirmed they are ready to accept delivery as per the week commencing date – Transport has not yet agreed what day this will be delivered

c. Purple = Transport has planned to delivery on this day however the customer has not yet confirmed they can accept delivery on this day

d. Green = Transport has checked in with customer and they have confirmed to receive delivery on this day

e. Grey = Delivery has been despatched in Rtis

How to view status of call off and production tracking

Follow the below steps to search for delivery dates.

Also check with Purchasing, Planning and Transport to see if any dates are likely to change

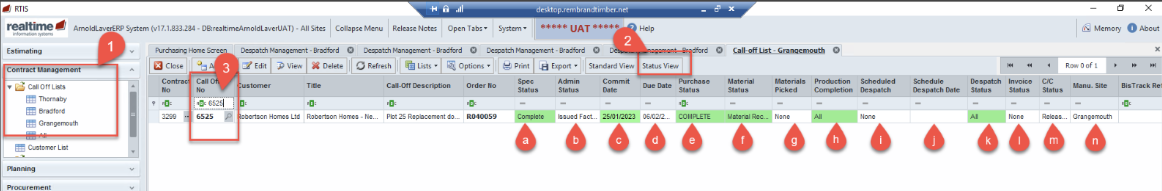

Status view of a call off

The call off full status are viewable here the due date column is the date the goods are due for delivery this is a week commencing date, speak to transport for actual delivery day

Admin status – show where the call off is

OTHER Status explained

Purchase Status -

Green = all goods received and complete

Amber = being processed

Material Status - Green = materials received Amber =Po placed Red= Material overdue

Material Picked – Green = all Products picked - Amber = Products part picked ( this will mean there will be goods to follow) - White –not picked yet

Production Complete – This information comes from the scanners in the factory, if your site uses scanning then this field will be relevant Green = All picked

Despatch Status

Invoice Status

Bristrack Ref – This is for Grangemouth use only – this show the Bistrack No the customer has been invoiced on

C/C Status

Production completion=

Scheduled despatched = when transport schedule calls off for despatching this updates this status

- None – transport have not planned anything

- New = this is a new call off and no communication has taken place yet with the customer

- Provisional = customer has been contacted by contract delivery and has confirmed they are ready to accept delivery as per the week commencing date – Transport has not yet agreed what day this will be delivered

- Scheduled despatch = Transport has planned to delivery on this day however the customer has not yet confirmed they can accept delivery on this day

- Confirmed= Transport has checked in with customer and they have confirmed to receive delivery on this day

Scheduled despatched date = this will be populated with the date transport has scheduled

Despatched status = this when the call off has been despatch in Rtis

- None = nothing despatched in Rtis

- Part= the call off has been part despatched in Rtis this means that there will be a balance /goods to follow

- All= all goods have been despatched in Rtis

Invoice status= shows status if invoiced or not

- None= not invoiced

- Part= only part invoiced

- All=all goods on call off invoiced

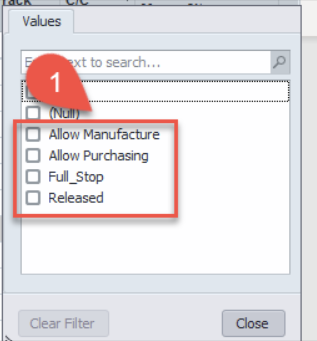

C/C Status= credit control status

- Blank= no credit control hold

- Allow purchasing = will only allow the call off to be progress as far as purchasing

- Allow manufacturing = will only allow the call off to progress as far as production

- Full Stop= the call off will not be allowed to commit

- Released = this means the call off was previously on credit hold and this call off has been

Manu.Site= this shows the site where the call off is to be manufactured

Doorset Production tracking – view progress through production

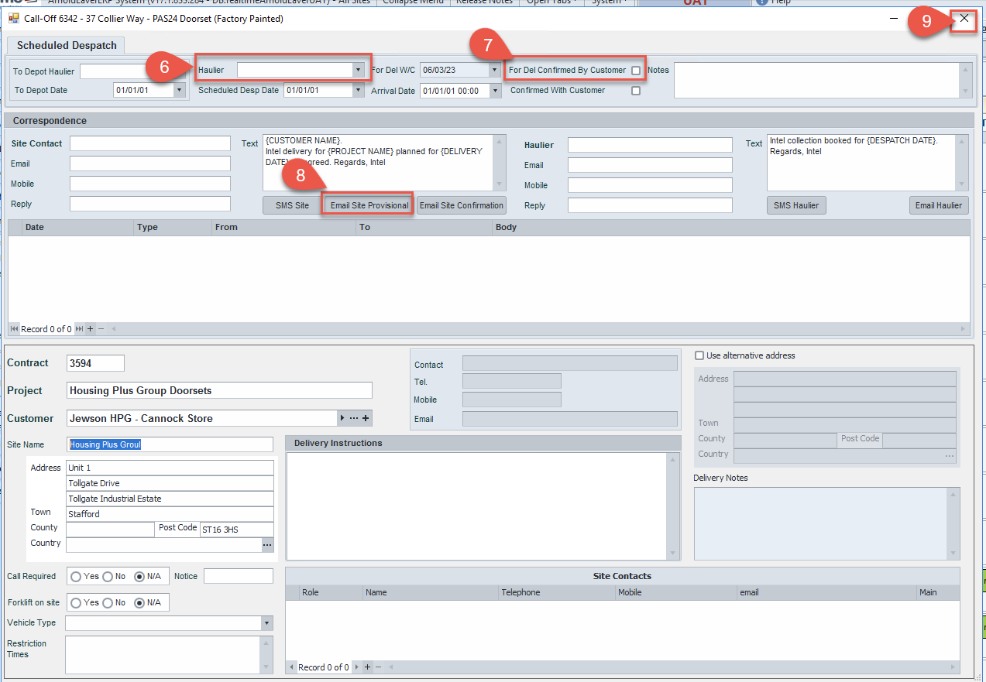

How to Update Transport - Automated email confirmation

Contract delivery will contact customers four weeks before delivery due date to confirm the customer is still requiring this call off on this week commencing date.

Once this contact has been made transport is to be updated by the contract deliver team by completing the below process.

When the customer has confirmed they are happy to take delivery the week commencing date tick the for del confirmed by customer box

View schedule of call off approved by customer

This process is completed by the schedulers and saved in SharePoint/Mondays board, there may be a need to view this when dealing with customer queries. This is what the customer will have approved prior to the call off being committed and sent for goods to be purchased /allocated ready for production

The below steps here will generate the schedule, schedulers will manipulate this export to a more customer friendly view, therefore it is always best to view the one saved in SharePoint that the customer had signed off/approved

How to produce schedule to send to the customer

A. Ensure that you only Select the call off required for the customer (NOT unassigned)

B. Select ok

Window closes

a. Check the selected call off is correct

b. Select print,

c. select the correct required schedule dependant on what is on the call off this will generate the schedule ready to send to customer

How to View credit status and get an order released by credit control

In Rtis/Realtime and Manual via email

Menu selected Contract Management ……………Topic from within Menu…Customer List….

The below steps will show you what the credit status of customer is and who the credit controller is these septs are used when entering a new contract if the first page of the contract set up has a credit red warning follow the below steps before proceeding with sending Material schedules that the BDM send to the customer

- Step A - is view credit status and who is the credit controller

- Step B - is the manual process for content on the email to credit controller

How to view credit status and who is the credit controller

manual process and content on the email to credit controller

Email credit controller

Copy in BDM

In subject matter type the following:

- Customer name

- Contract number

- Call off number/s

In the body of the email include the below:

- Call off dates

- Ask for order to be released

Set a reminder flag for 48 hours after sending email to chase:

- Select follow up flag from top tool bar of email

- Select add reminder

- Select a date to be remaindered 48 hours away

- Adjust the time by selecting a time from the drop-down arrow

- Click OK

C - View call off on credit hold and export to excel

How to add an Alternative address

Before changing the address, it is essential that the status of the call off is checked the below steps cover all status

Admin status at issued to purchasing covering Direct deliveries

Unless this is a direct delivery changing the delivery address does not affect purchasing

If this call off is a direct delivery, speak to purchasing before any changes are made to the call off

If purchasing has not placed the purchase order to the supplier proceed to steps 10-16

Admin status at issued to factory

Recall and replace the transport sheet that has been issued to the factory

Communicate with factory to let them know that the delivery address is being changed and to destroy the current transport sheet in the production pack

Communicate with team that print the production paperwork to let them know the below.

5.1- Changes are being made to the delivery address

5.2- Once you have changed the address, inform team who print paperwork that the NEW transport sheets are ready to be reprinted and taken immediately to the factory

Once step 5.1 is complete proceed to change the delivery address by following steps 10-16

Despatched but NOT delivered or invoiced

Recall and replace the despatch Note and transport labels

- Communicate with transport to let them know that the delivery address is being changed and to return the current despatch note

- Communicate with the factory to let them know that the call off will need its transport label changing due to an address change

- Communicate with the team that creates the despatch note that the address change is to happen

- Once you have changed the address, inform team who print paperwork and who create the despatch note that the NEW documents are ready to be reprinted and taken immediately to Transport and factory

Once the above communication has taken place proceed with making the address changes by following steps 10-16

Invoiced status

Once a call off has been invoiced a delivery address CANNOT be changed if the goods are to be returned and re delivered follow the returns process

How to change a delivery address

In the delivery notes field include details of who requested the change and who made the amendments

Close the window by selecting the X

Check the alternative address column this should now be RED and read site New Address, save and exit the call off

Inform Paperwork/despatch/factory/transport teams that the address is now changed in the call off and that the relevant new paperwork can be printed and used straight away ensure all old paperwork is collected and disposed off

How to View Audit log

This process is available to authorised users only. Contact joanne.hardy@inteldoors.co.uk to gain access to this process within Rtis.

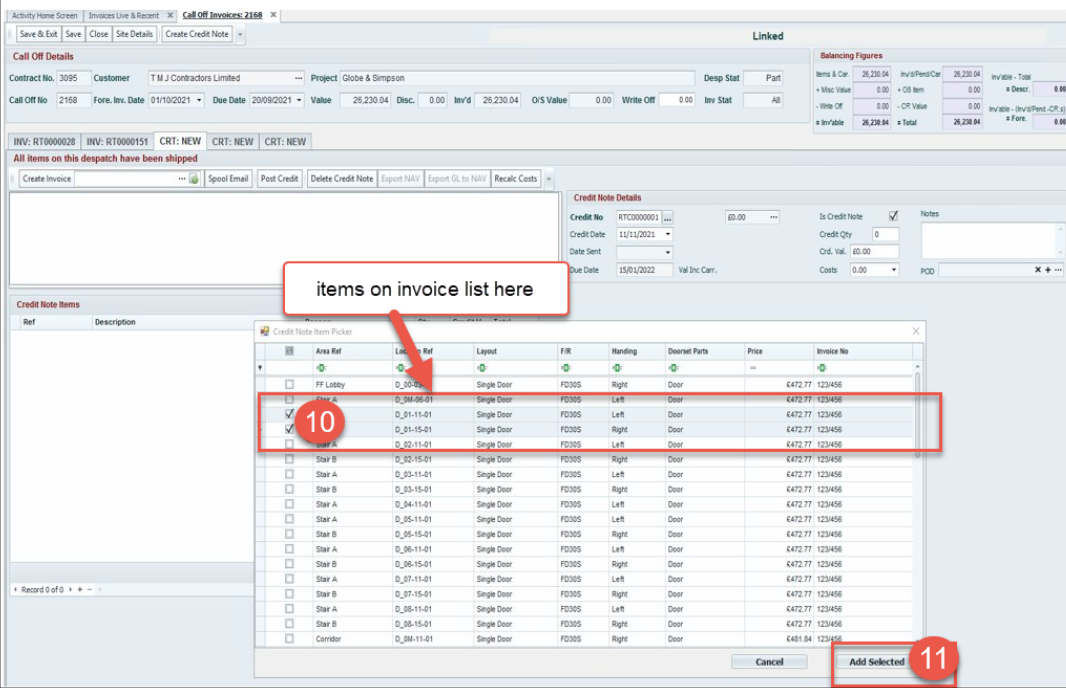

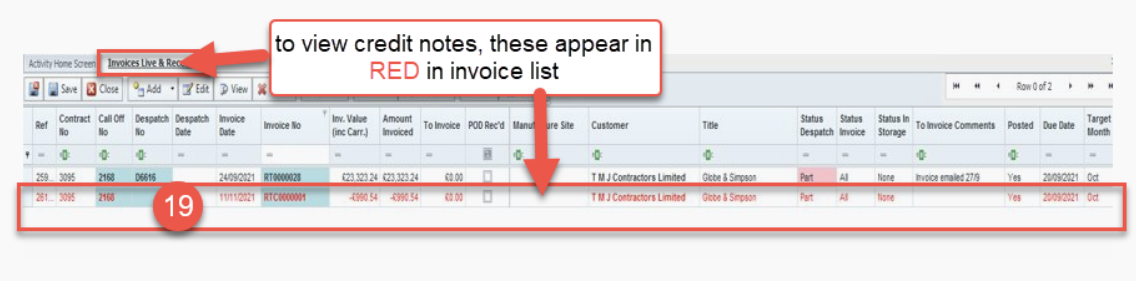

How to raise a customer credit against an invoice - Grangemouth Process only

Customer credits must first be authorised by site manager and relevant paperwork completed before being processed by authorised user

Bradford process is in the contract delivery menu section

Search for the invoice the credit is to be raised against and select the row by clicking in the line

Select the + to add a manual credit – here add a description and reason for the credit also include the invoice number

This shows manual entry

The credit note is available here select the three little dots… to view and check the credit note

How to create a loose item

A loose item is a product that does not need manufacturing such as.

- A door only

- Ironmongery

This is created from the call off line by following the below steps.

Create a new call off in the normal way

If more items are required repeat the above steps until all loose items have been added

Pop up window appears asking are you sure you want to recreate purchase requirements select OK to continue

A new pop-up window appears after a few seconds saying update complete OK select ok to continue

When a call off is to be delivered direct from supplier to customer

Select the drop-down arrow in the admin status column and select Direct Dly this will be clear to purchasing – planning and transport that the supplier is delivering these goods

When the call off is free of charge for the customer

If this item is authorised as free of charge for the customer tick the FOC box this then does not affect the credit status of the call off credit control do not see a call off that has this ticked

When a call off is of high priority and requires purchasing to act upon straight away

- In the description column enter AFTERCARE 12345(aftercare related no)

- Once call off complete email purchasing @inteldoors.co.uk /flag to your onsite purchaser that this is urgent

- in subject field of email write aftercare

- in email enter call off number and request urgent attention

- if your onsite purchaser is not available by emailing the purchasing inbox this will be pick up by a member of the wider purchasing team as a matter of priority

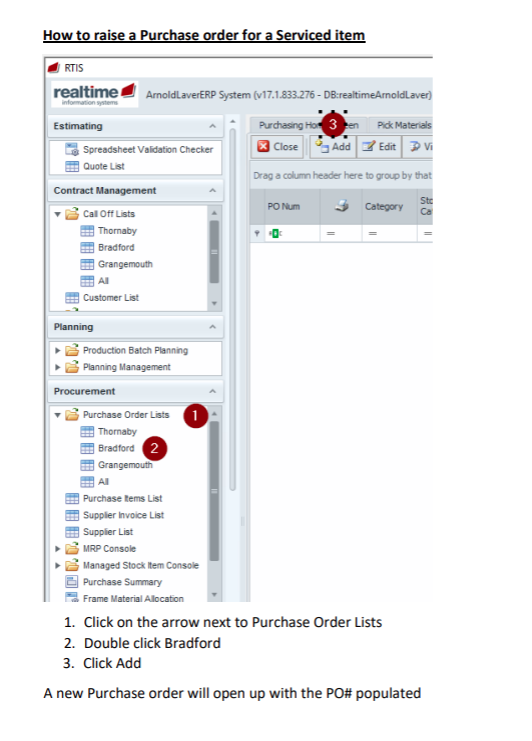

How to raise a Purchase order for a Serviced item

For any queries email purchasing@inteldoors.co.uk for help and advice

How to delete a line in a PO

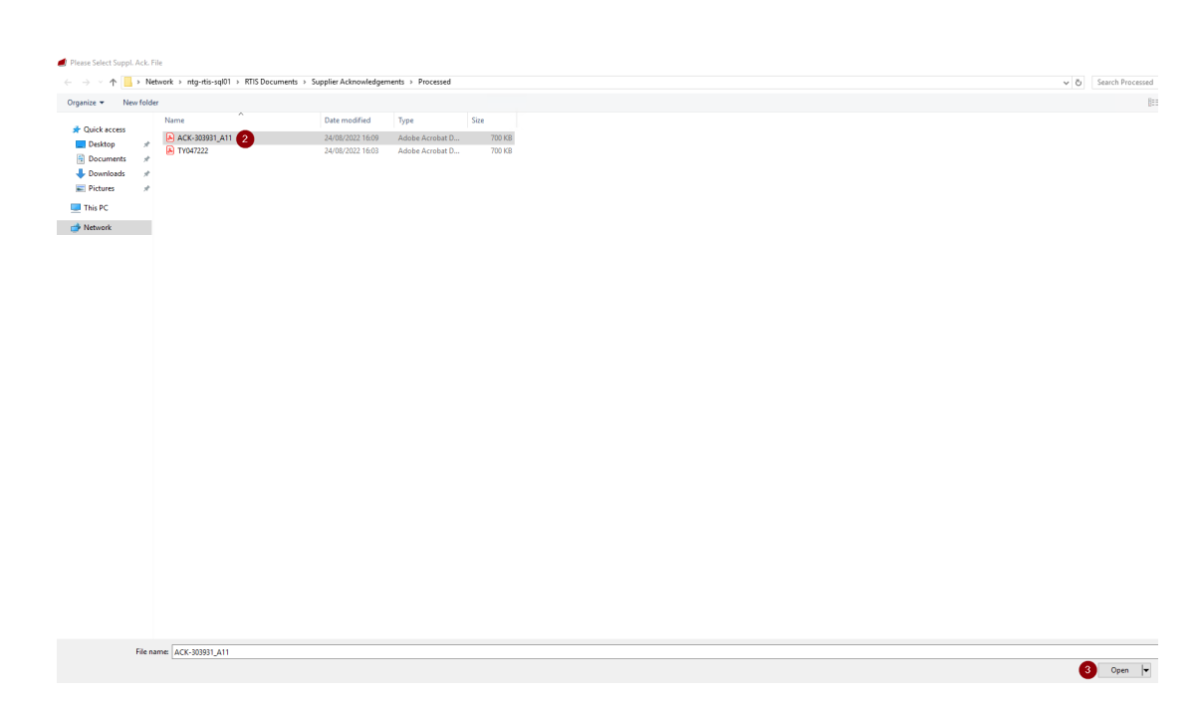

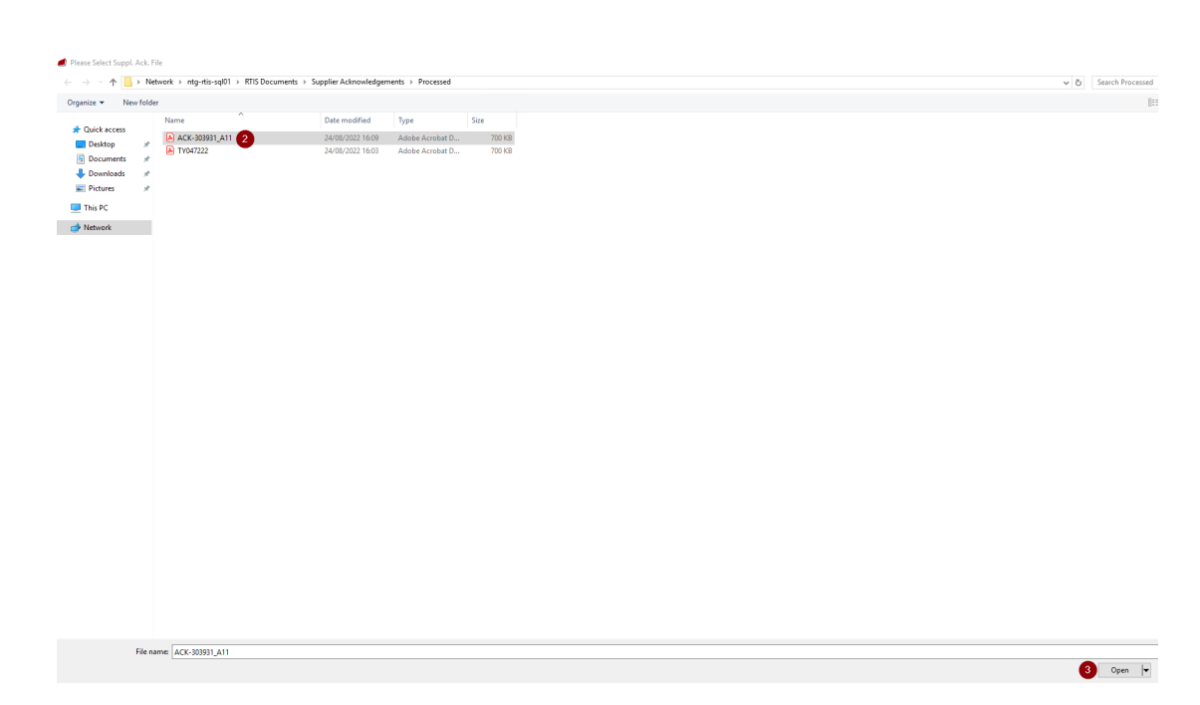

Saving Supplier Acknowledgments

For help and advice email purchasing@inteldoors.co.uk

How to process returned stock

- Before this process is completed in Rtis authorisation by branch Manager/Director must be obtained and this form must be completed 05b.How to Process Returned Stock - Credit-Note-Form_Ver1_Dev3.pdf

- Credit notes are NOT to be issued until the stock has been returned and inspected

- Having access to the original invoice is needed to complete this process

Stock returned needs to be reworked

Issue credit note - completed by authorised branch person link to training document 06.How To - Raise a Customer Credit against an Invoice.docx

Raise a new call off, this allows the goods to be re delivered. To be completed by authorised person

usually scheduler link here to training document 10.How to Create a Loose item v1.docx taking note of steps 3-6 below

In the description of the call off enter “re delivery of call off 1234” (this is the original call off number)

Add misc. item

Copy the description from the invoice for each item

Take the price from the invoice

Stock items Returned

Raise a credit for the customer – to completed by authorised branch person link to training document 06.How To - Raise a Customer Credit against an Invoice.docx

Complete stock adjustment to be completed by authorised person this is usually a purchasing process link here to the training document 06.How To - Complete a stock adjustment v1.docx |

How to process returned stock - credit form

How To - Customer returns manual process - Bradford

This is the manual steps that are required to take place for a customer return. Departments involved are.

- Contract delivery

- Stock control

- purchasing

- Transport

- Goods in

- Management approvals

Customer request return

Contract Delivery –

- Complete credit note form and send to Ben M link to form here 05b.How to Process Returned Stock - Credit-Note-Form_Ver1_Dev3.pdf

- Print off a copy of POD highlight what is to be returned and send to Ben McCreath

Stock Control BM Complete collection note 05d. Customer Collection manual note - Bradford v1.xlsx

Stock Control BM -approves return and requests contract delivery to raise a call off for the return this is so transport can see and plan for the return |

Contract Delivery raise a call off as a loose items see process steps 10.How to Create a Loose item v1.docx

Misc. item stating collection of call off 1234 include detail of doors/frames and Qty`s

Stock Control BM Hand 2 copies of collection note to transport one copy is for customer one to be returned with the goods

Transport arranges with customer a collection date

Driver collects return gets customer to sign paperwork

Goods In KH Goods arrive in Bradford checked upon arrival

Goods In KH Paperwork handed back to stock control

Stock control BM consult with Contract Delivery/ Production

if goods are to be reworked /back to stock

Management Approval required from BM GO JN MI to choose below option

|

Contract Delivery if applicable Issue customer with authorised credit note

Stock Control Scan and save the collection note to the supporting files in Rtis on the contract adding the below as a description

- Customer return call off 1234 original call off 5678

Customer Collection manual - Bradford

Planning

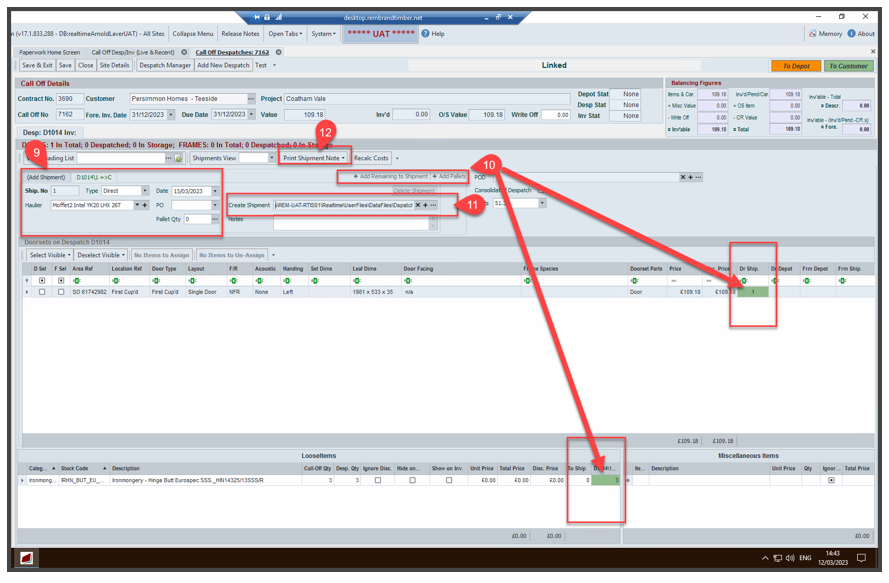

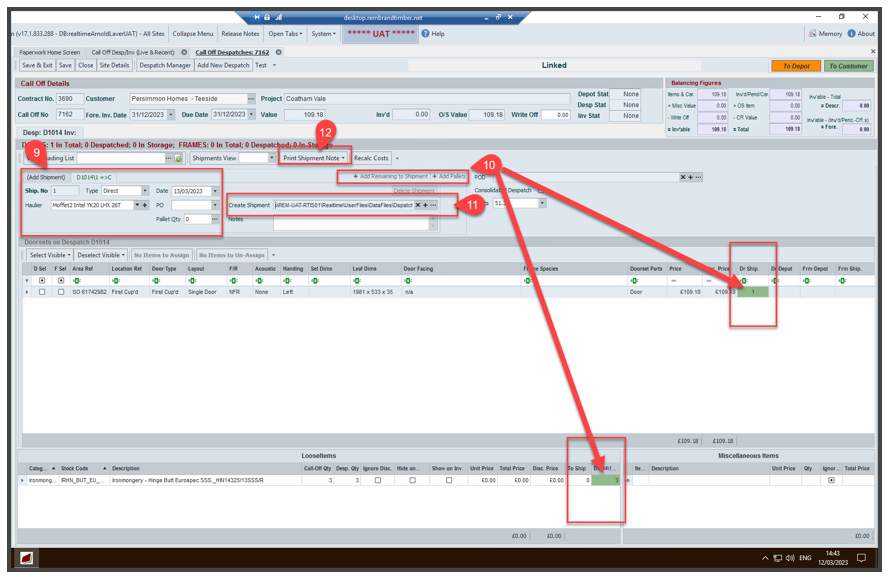

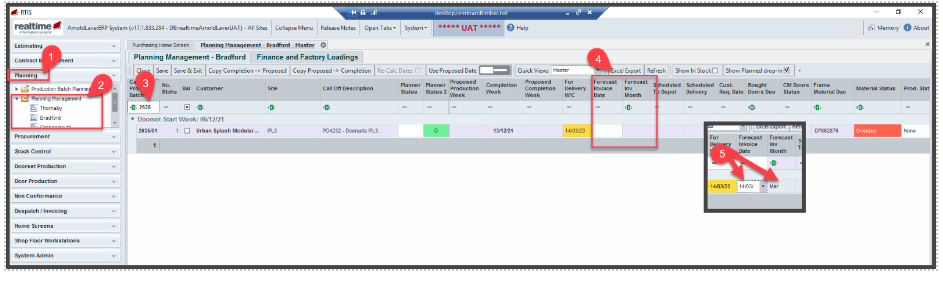

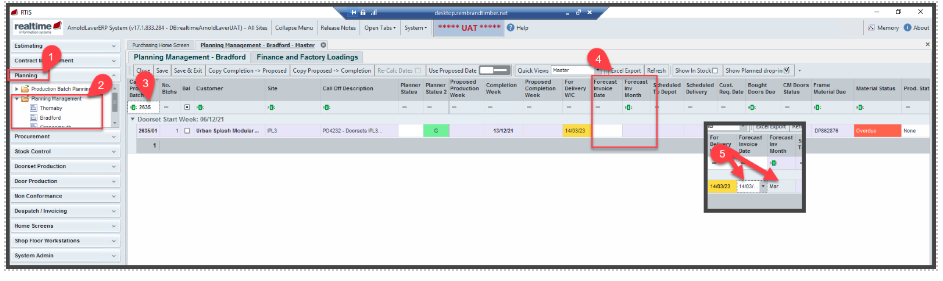

How to view and Understand Planning Management information v2.4

There are several features in this planning management view which can be customised and useful

- Columns can be dragged and dropped to a different location

- Columns can be removed by left clicking, holding and dropping above the column header

- An excel export is available by selecting the excel export tab

To view planning management from the Planning menu, select the Planning Management folder and branch

This opens the planning management view each column`s detail is explained below

- Call off Prod Batch – this is the call off number first 4 digits followed by the batch number – no batch number means the call off has not been committed and cannot be planned

- No Batches – states the No of batches for the call off

- Bal – is short for Balances if all items on the call off have not been despatched a tick appears in the box and is highted in yellow

- Customer – customers name

- Site – site name

- Call off Description – details of the call off i.e., plot No`s

- Planner Status – this is a custom column and the codes and colours ae unique to the site – speak to site planner for a list of what these mean

- Planning comments – this is a free text box and is used by the planner and other agreed departments speak to site planner for how this is used and any break down of codes used

- Cont.Man – this is short for Contract Manager; this is the initials of the contract manager who set up the contract

- Spec Status – this will state either.

complete – which means the customer has signed of the specification

None – means awaiting customer sign off, communicate with the contract manager to find how why this is not complete

- To Purchasing Deadline – this column will flag up any issues with purchasing, dates appear when stock has been ordered to fulfil the order and needs to arrive on a certain date to complete the order on time

- Admin Status - there are several statuses which are driven by processes completed at the call off level which reflect in here these are

Issued to purchasing – Contract manager has issued the call off to purchasing and the call off is committed

Processing – Contract manager is currently processing the call off and has NOT been committed

Direct Dly – Purchasing have marked this as a direct delivery which means the supplier will deliver direct to the customer

Issued to Factory – The printed paperwork has been issued to the factory ready to start production

Provisional – this is the default setting that all call off`s start at

Sent for approval – Contract manager has sent off to customer a copy of their specification for them to approve this has NOT been committed

- Doorset Start week – this date is the date when the work is planned for

- Proposed production week – this should be blank unless the authorised planner changes this date

- Completion week – date here is the week the call off is to be completed

- Proposed completion week - this should be blank unless the authorised planner changes this date

- For Deliver WC – date here is the week commencing when the call off is to be delivered – for exact delivery date speak with planner/transport

- Scheduled Delivery - this should be blank unless the authorised planner changes this date

- Cust, Req, Date – date here is when the customer wants the goods delivering

- Forecast invoice date – this column must always have a date if there is no date the planner will need to rectify these otherwise goods cannot be despatched

- Forecast invoice month – details the month the customer will be invoice

- Prod. Status – choices here are all/part/none – this is driven by scanning if no scanning has been completed this will remain blank

- O/S Value – value of the call off

- PD – this column shows the QTY of doors to be manufactured

- PF - this column shows the QTY of frames to be manufactured

- PGO – Production Glass opening

- Screens - this column shows the QTY of screens to be manufactured

- Manual Qty – this is only to be used as a forecast tool, before it is scheduled, this will be updated by the scheduler

This view is set out by the site to show what is being manufactured on a particular day

a. Each day

b. No Call offs

c. Total value for the day

d. Qty of doors/frames/screens planned for manufacture

This view shows all call offs NOT planned; planner will communicate with contract manager/purchasing to resolve reasons why these are not ready to be planned

a. 01/01/01 - means not planned

b. Bal – These are balances still to follow

c. Planner Status – needs attention from planner/contract manager/purchasing

d. Comments – many needs addressing so planning can proceed

e. Spec status - many need addressing so planning can proceed

f. Many columns with no data - many need addressing so planning can proceed

g. Dates - means not planned

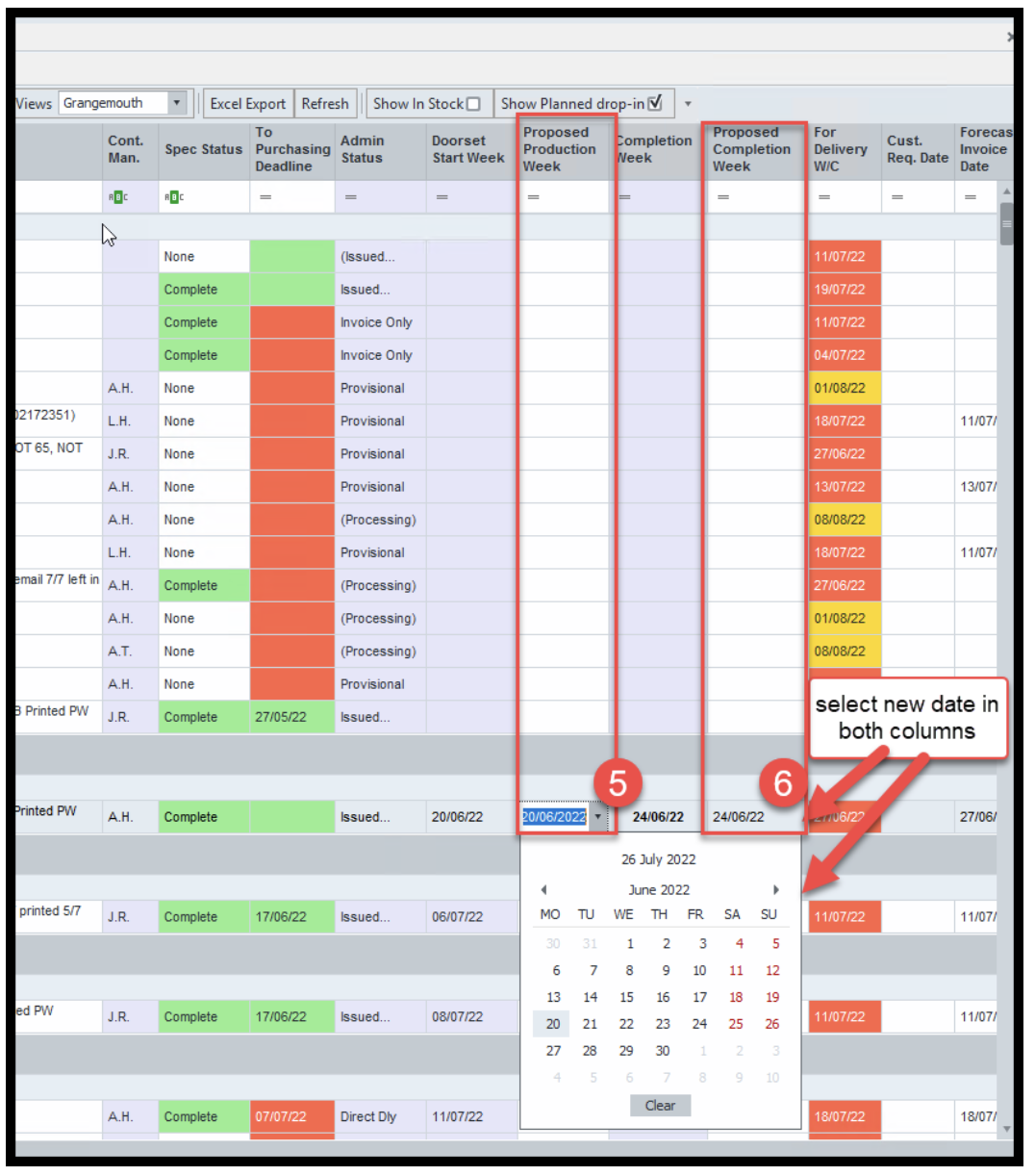

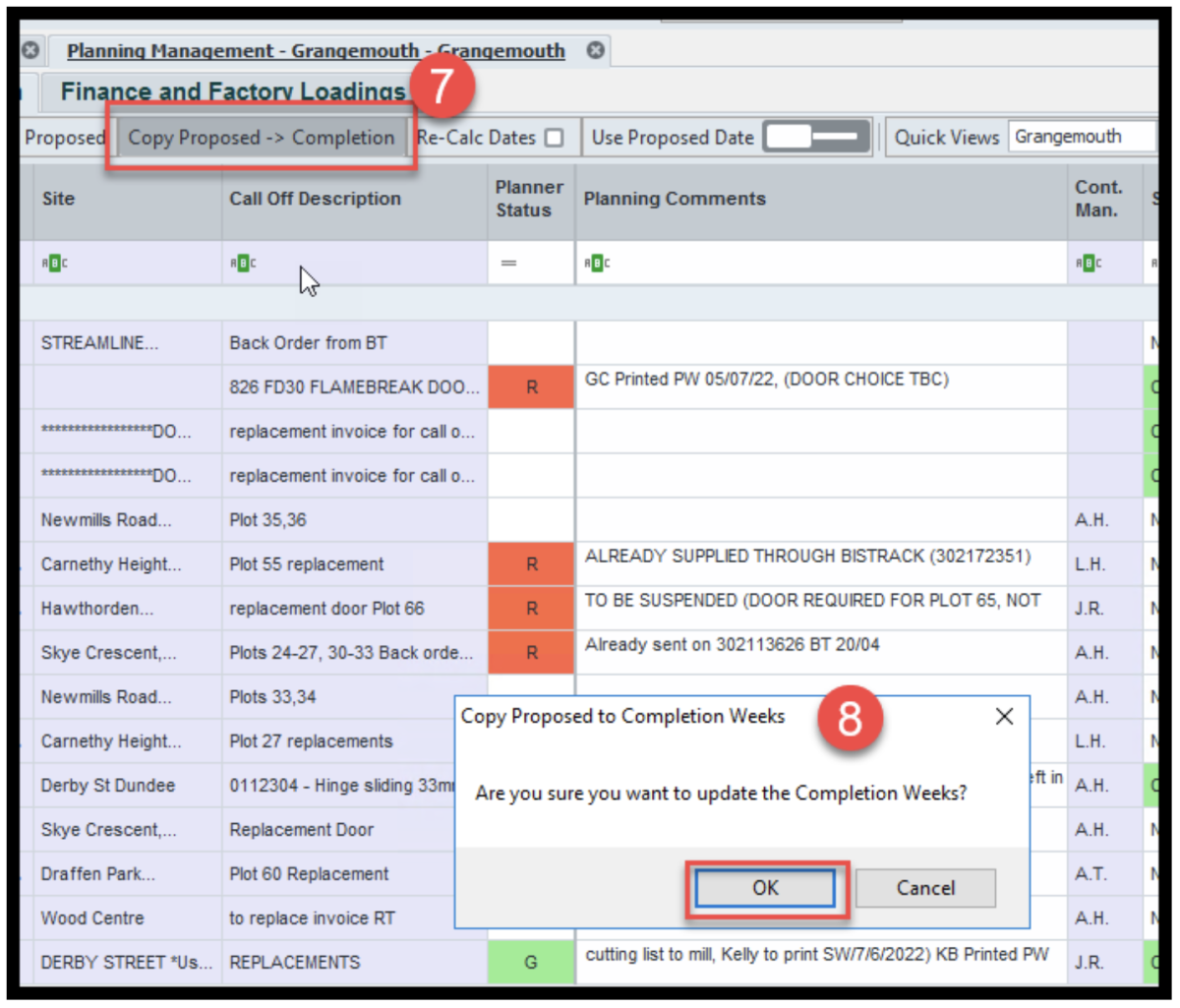

How to - Move a call off and replan

Below are the process steps and images of how to move a call off in planning management

In the proposed production week and proposed completion week columns select the date you wish to change to

How to use Batch Planning

Not currently used by the business contact rtissupport@nationaltimbergroup.com for an update on this

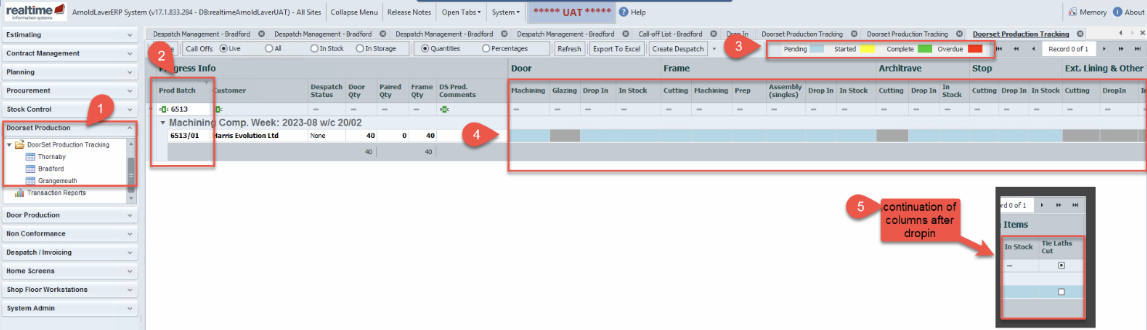

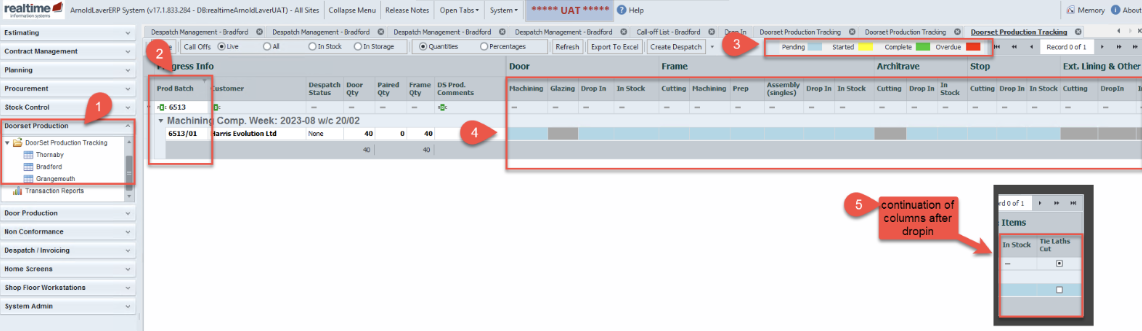

How to view doorset production tracking

This view displays exactly where in the production process a call off is

Doorset Production tracking – view progress through production

How to update forecast invoice date

- When despatching if the below message appears the forecast invoice date must be updated in planning prior to proceeding with the despatch

- Communicate with planning or follow the below steps to update the forecast date

No Despatches can be created without a Forecast invoice date

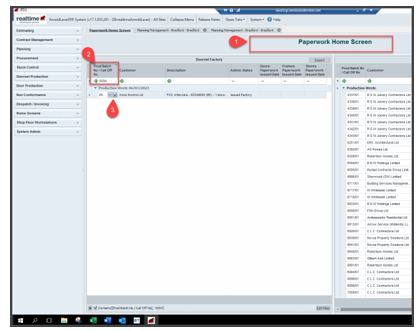

HOW TO - Print paperwork from desktop home screen

Your Rtis open screen desktop will be set to Paperwork home screen if you regular print paperwork if you need your home screen setting to this contact rtissupport@nationaltimbergroup.com

Choose from the pre-set dropdown what is to be printed this will be pre agreed when Rtis is set up, if unsure speak with your line manager

To print individual sheets, follow the below steps

New window opens ensure the issue button is selected

Procurement

How to create a PO for managed stock

In Rtis

Steps 1 – 23 how to raise and send a PO

Steps 24 to 32 how to amend a PO

from the procurement menu select managed stock item console Grangemouth

New window opens select create new PO

PO category field select from drop down arrow - MDF

From stock category field dop down select - frame components

Search for and select supplier

Select the managed stock item tab

Select category (architrave)

Select the load tab

This then loads all the managed stock you can now select what you want to order

In the to process qty Colum enter the qty required

Select the process to open purchase order tab

Return to the PO by selecting the purchase order tab with generated PO number

Check the correct items have pulled through

Select update unit and pricing tab

Check and amend the unit

Check and amend prices ensure correct price is entered

Select sub date the date you raise the PO

To populate the required date field, select the PO Call off tab from the right-hand side

Date sent select from the drop down the day PO sent to supplier

Sent box tick this to confirm PO sent to supplier

Select the Print tab and select from the drop down external

This generates the PO as the email function in Rtis is currently not active save the PO in a folder (you may already have a folder you keep PO in if not please create one)

Open outlook and attach the saved PO and send to the supplier

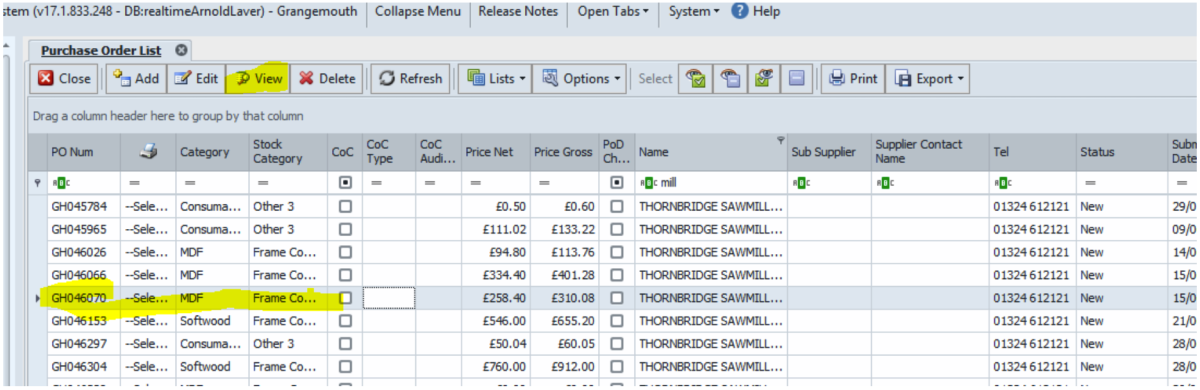

How to amend/edit an open PO one that has not been booked in

From the procurement menu select purchase orders Grangemouth

Search for the PO you want to edit

Click on the PO line

Select the edit tab

PO now opens

Select the product line you wish to edit by clicking on the + icon on the left hand side of the line (see image below)

Once all amendments are made save and reprint ensure if you have already issued a PO that the amended PO is sent to the supplier

How to Raise a PO for non managed stock

In Rtis

Menu selected → Procurement → Topic from within Menu → Purchase Summary

Filter the Manu. Site to Grangemouth

Enter call off number in the call off search box

Working from left to right select each of the Timber fields and review requirements

Double click in each field

This opens new window

View this window if no stock to view in here tick the box in the top right-hand corner next to Not Req

Status auto populates to Not Required

Select save and exit

Window now closed and returns to purchase summary

When a field selected has stock requirements purchaser then reviews the stock and decides if this item is from stock or is to be purchased, if from stock select all from stock if to be purchased select not from stock

All timber will be ordered from the mill the selection here is not from stock

update the status to PO placed this is selected from the drop down

Comments can be added into the comments box which is a free text box

Save and exit making a note of the call off number

Window closes and returns to purchase summary

When a goods needs to be order select MRP console Grangemouth from procurement menu

This opens a new window

Select Timber from drop down next to material group

Select create new PO take note of the number

Select the category from the dropdown arrow i.e., hardwood

Select supplier from drop down this opens new window

Search for Thornbridge sawmill click on the …

Select the material requirements tab

Select pick call off tab

New window opens search for call off and select …

This pulls through the material requirements

View the requirements

If all are required select the set all Bal qty to order

Select process to PO tab

Click OK

Select the PO with the number you made note of in step 20

Select sub date this is the date PO created

In the delivery address/call off box select the call off tab enter the date the timber is required, this populated the req date filed

Tick the fax sent box this confirms PO /cutting list issued to the mill

Select the instructions/notes tab to add any comments required to communicate to the mill these will show on the PO only not the cutting list

Select the mill requirements tab

This opens new window select print frame cutting this then generates the cutting list

Select the printer icon select the correct printer and print

A pink and yellow copy of the cutting lists is also required using coloured paper already in stock print these copies ready to take to the mill

Select the print tab this generates the PO this can either be emailed to the mill or printed and taken across to the mill office when the cutting list goes over

Save and exit

When you return to the purchase summary and click in a different field your field will be updated with PO number and turn orange until the goods arrive and have been booked in

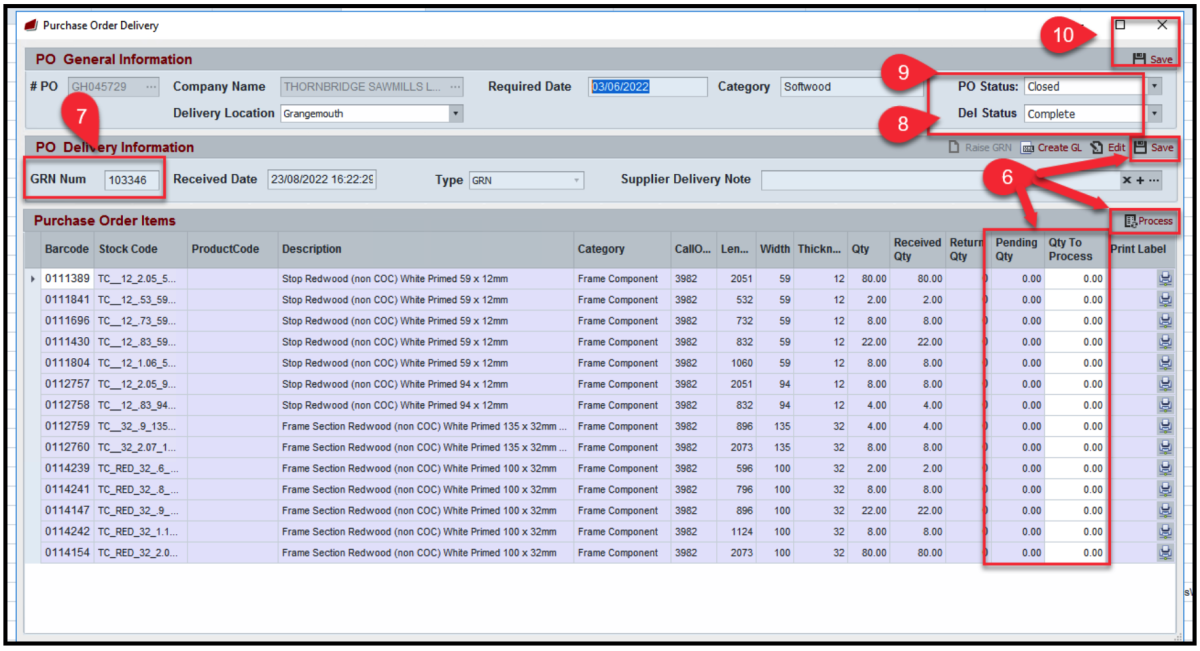

How to GRN and save delivery note

- How to GRN goods received steps 1 to 9

- How to scan and attach the delivery note to the Purchase order follow step 10

New window opens search in the PO Number field for the PO related to goods received and click on the word select

Pop up appears and asks if you want to create a new delivery for PO call off select Yes to continue

Select the correct status from the drop-down arrow in PO Status

- If all goods arrived select closed

- Choose different status to reflect correct situation with the goods

Select the correct status from the dop down arrow next to Del status

Select complete if this completes the PO

- Select other status that reflects the state of the goods if not complete

How to save and attach delivery note to PO

Scan deliveries note and save in the W Drive >Supplier Delivery Notes >Pending folder with the following naming convention

- PO Number _GRN Number example here GH045742_102394

Rtis runs a programme every 10 minutes and this will auto save the Delivery note to the purchase order

File the hard copy of the delivery note away

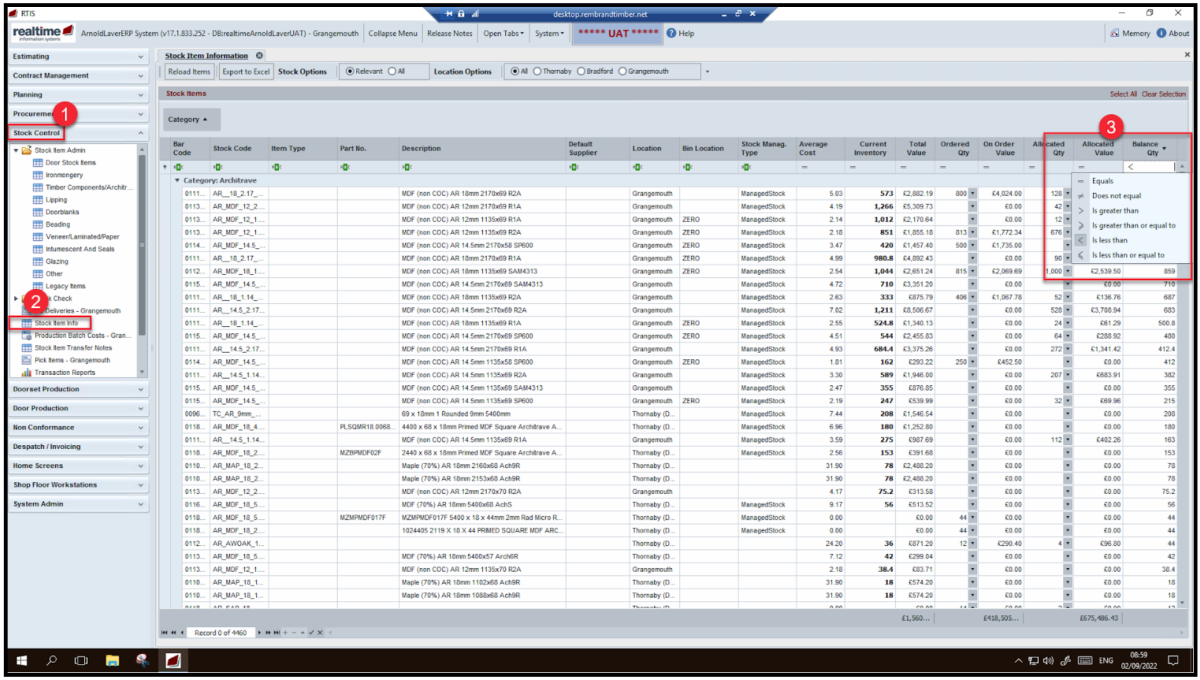

How to Set minimum Stock Quantity Level

How to set the minimum stock levels

How to view the set minimum levels

How to check Stock levels

How to view stock levels

How to View a PO and the Mill Cutting List- Grangemouth process only

In Rtis

Menu selected → Procurement → Topic from within Menu → Purchase Orders Grangemouth

Click on the PO line

Select the Edit tab

How to process a supplier return

Any questions about this process please contact purchasing@inteldoors.co.uk

Complete Supplier return form- follow this link for the form 04.Supplier Return Form.pdf

Ensure the following is complete.

- PO No

- Call off No

- Description

- Qty to be returned

- Add supporting photos

Email the completed form to purchasing@inteldoors.co.uk in the subject field of the email put SUPPLIER RETURN this will ensure the email is given priority

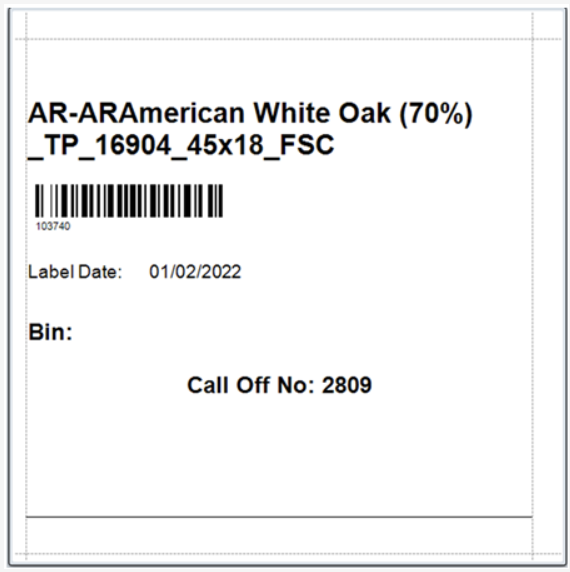

Once the supplier return has been generated by purchasing an acknowledgment will be emailed back with a label as per image1

Attach the label on the quarantined goods in the warehouse so everyone knows they are to be returned to the supplier and not to be used

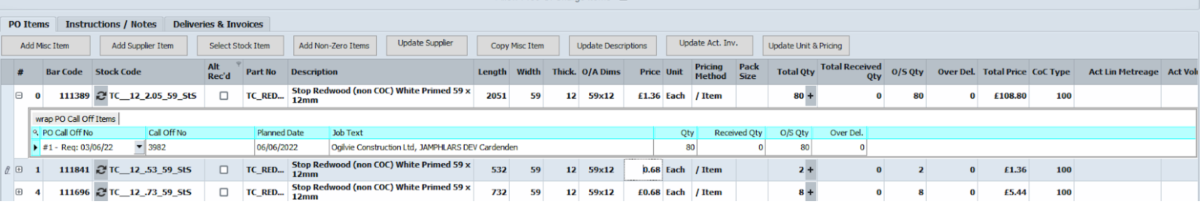

How to Handle Purchase Ledger queries

- When purchase ledger has a query, the below list are areas in Realtime that are to be checked to support purchase ledger in resolving their query

- Below are what to check and cross reference, Investigate and amend any discrepancies, communicate with suppliers and purchase ledger

- If this does not solve the query log the query with rtissupport@nationaltimbergroup.com

View the supplier acknowledgement by selecting the … and check this match what is on the purchase order

Check GRN –

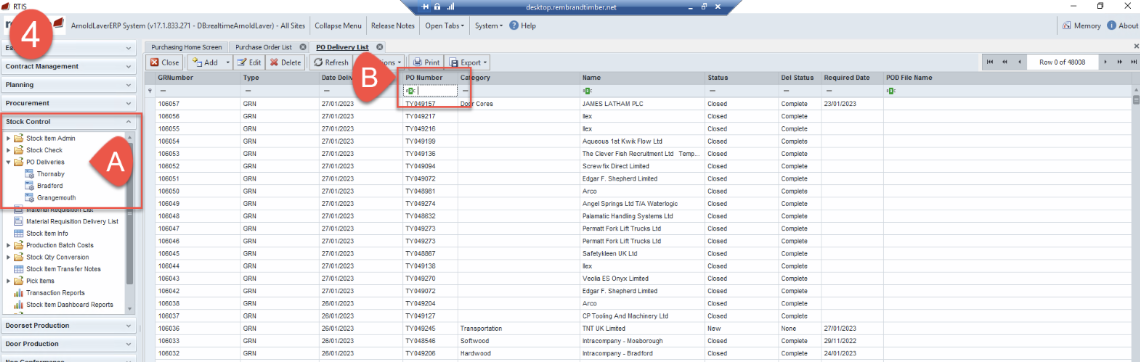

- from the stock control menu select PO Deliveries select you branch

- search by PO number to view GRN

How to use the purge button when materials doubling up

- Here is a temporary solution for when an error in Rtis arises where the material requirements are doubling up

- When the scheduler is creating a call off and saves, if the duplication of materials is an issue, an error message will appear stating there is a problem with material requirements duplicating

- The scheduler can then follow the below steps to correct this

Rtis are working on a permanent solution when this is resolved an update will be circulated

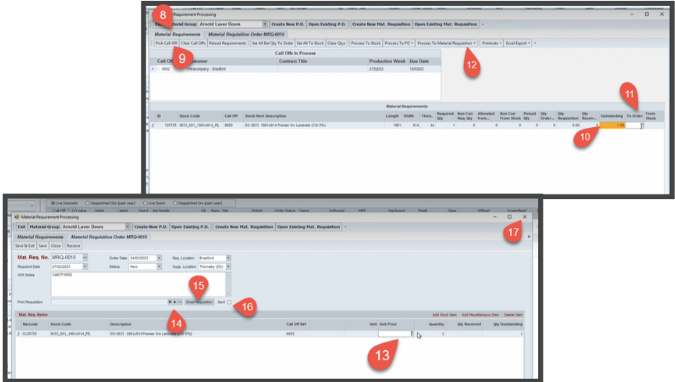

How to raise a material requisition stock transfer request

This part of the process is completed by purchasing

Raise a material requisition – requesting branch

How to and when to use Monday.com and inteldoors cost matrix - on Hold

How to create a stock code

- Stock codes are created by authorised purchasing teams

- Manufacturing codes and descriptions MUST be used when creating new codes, this creates a consistent naming convention to all codes created plus helps other colleagues who must identify stock from a description

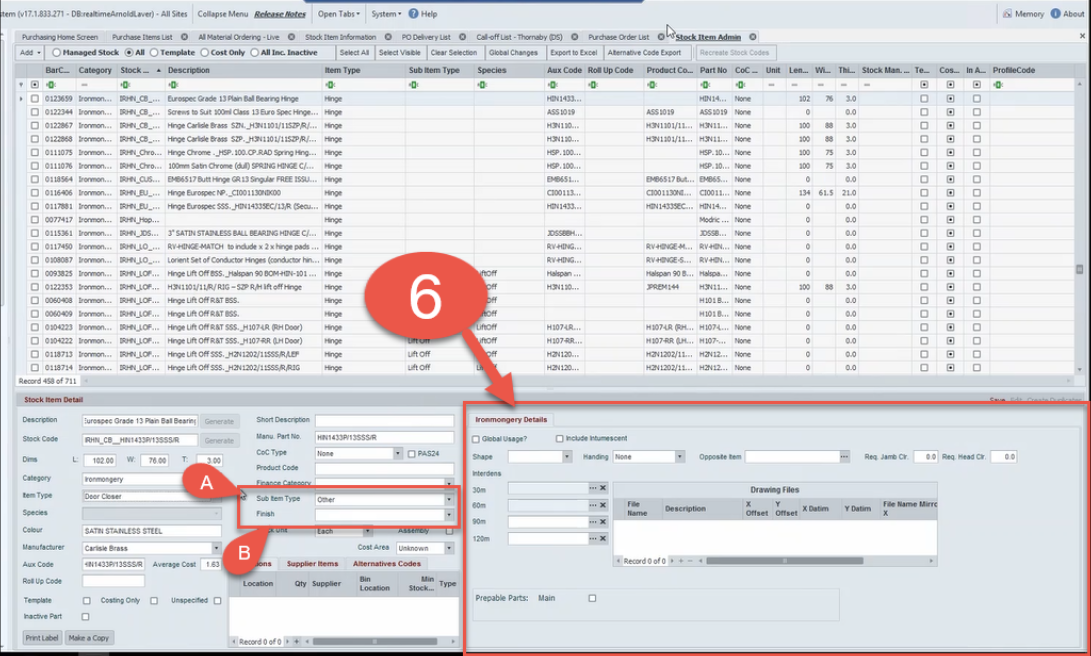

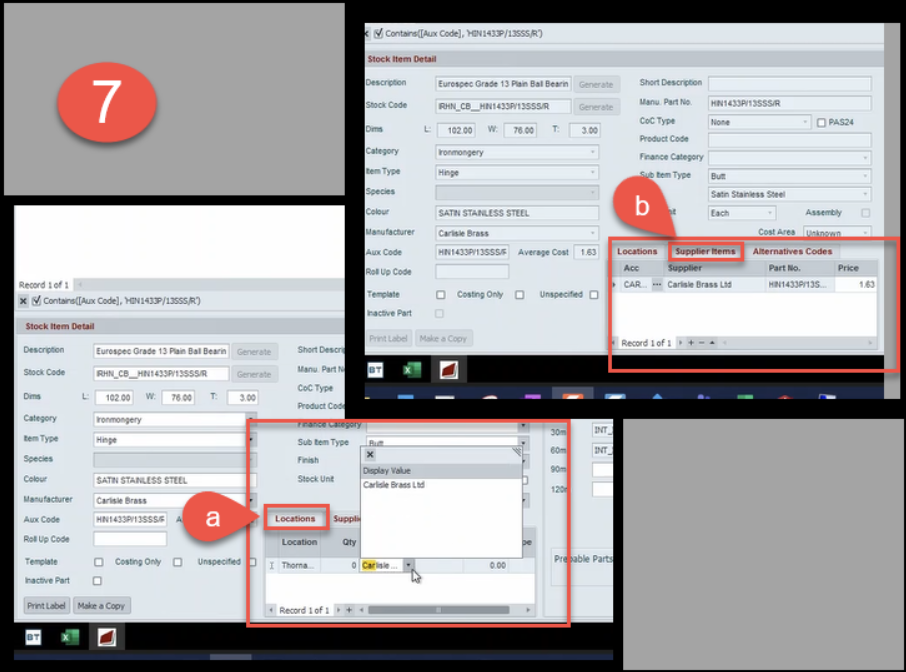

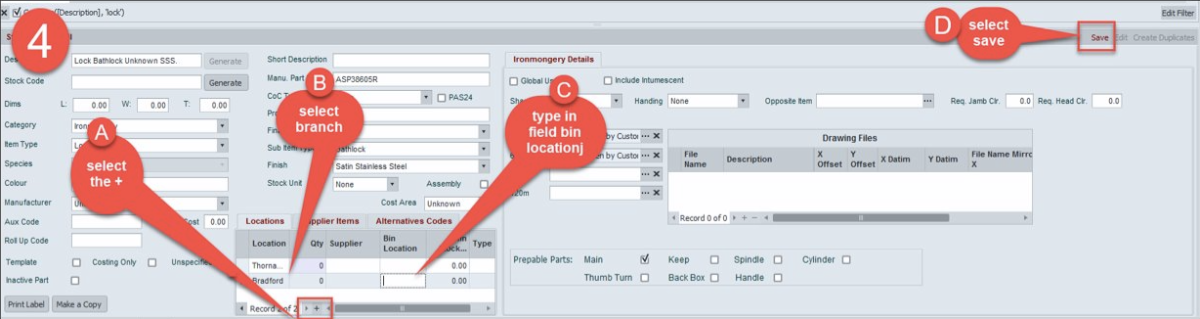

- Below is an example of a code created for Ironmongery the principle is the same for all codes created, however depending on the product different fields and information will need to be inputted, any query about unknown information or what to enter into a field in the first instance contact your designated superuser or log the request for help with rtissupport@nationaltimbergroup.com

This opens new window from the dropdown arrow of the Add tab select Add Ironmongery (this will selection is an example if you selected doorbanks when the drop down is selected it would say doorblanks)

Complete all fields as below in the stock item detail section in the lower half of the screen

Description – using the manufactures catalogue from the supplier

Manu Part No – enter supplier product code, copy this code

Aux code – paste code into this field

Category - ensure correct category is selected

Dims – enter part dimensions

Item type – select from drop down

Colour – enter from supplier description

Manufacture – select the supplier from the drop-down

Stock unit – select how these are sold from the drop down

Stock code –

select the generate button

pop up appears displaying the code select yes to proceed

select save

saving will lock and grey out the areas that have been completed

Select edit to continue

- Average Cost – find the cost from the price file, copy the Manu Part No and search in price file

- Save

Complete all fields as below in the Ironmongery details section - depending on what is selected from the Item Type in step 4 different criteria needs to be completed – this section is crucial to what scheduling select and the instructions that are available and selected for the production team, all fields must be completed.

- Ensure that the sub item Type from the stock item section is correctly selected as these drives what is to be completed in this details section

- Finish – select from drop – down as per manufactures description and save

Here is a link to a short video showing an example of the importance of the detail in this section 06.How to create a stock code - Ironmongery Detail video.mp4

How to Create a stock code - Ironmongery Detail video

Here is a link to a short video showing an example of the importance of the detail in this section

How to add pallets

This process is a Bradford process completed by purchasing

How to raise a Purchase order for a serviced item

Stock Control

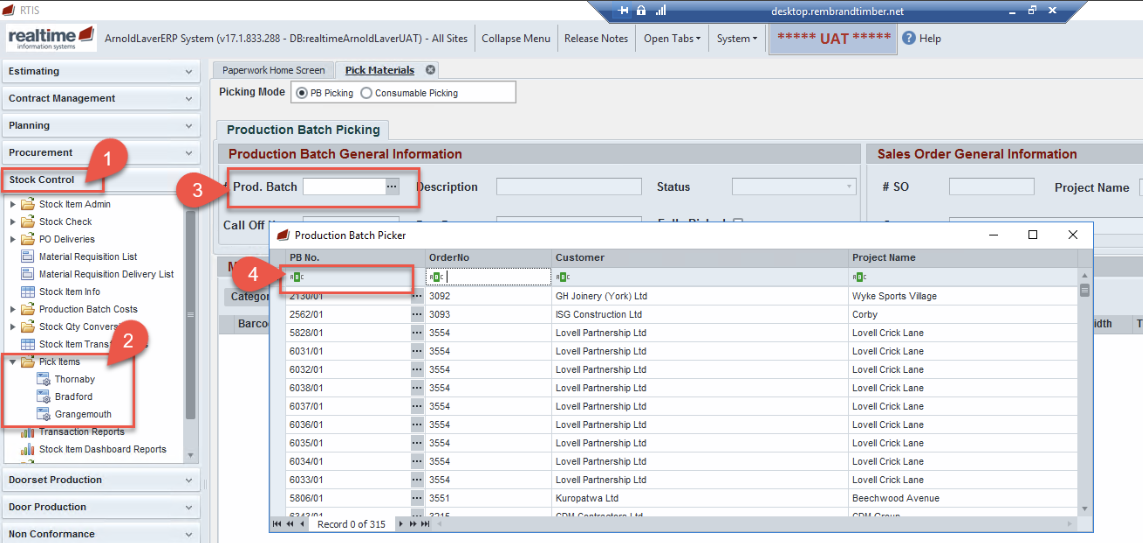

How To Confirm Goods Picked